Bio epoxy resin, green, low-carbon, environmentally friendly materials that meet the trend!!

Kelly Chemical provides green epoxy resin with high biomass content and high quality, and you and I will contribute to a better earth for the next generation.

Epoxy resin is an important thermosetting material, widely used in daily life and industrial production. It has excellent adhesion, high mechanical strength, low curing temperature, excellent heat resistance and solvent resistance, low shrinkage after curing, and good electrical insulation properties.

(Further reading:Toughened epoxy resin-CSR core-shell technology to solves the problem of brittleness!!)

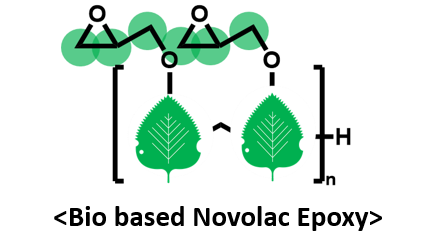

However, petroleum-based synthetic epoxy resin has the characteristics of high carbon emissions and is not easy to degrade and recycle, causing great harm to the environment. Based on the desire for the sustainable development of the earth, epoxy resins from bio-based sources have gradually attracted human attention. Brands advocate the use of low-carbon materials to develop products, and Bio-Epoxy resins can partially replace traditional petroleum-based products. , Alleviate the oil crisis, reduce environmental pollution, and then achieve the vision of carbon neutrality. Among them, some bio-based epoxy resins can be compared with bisphenol A (BPA) epoxy resins in terms of thermal properties, mechanical properties, and insulation, and some are superior to traditional bisphenol A (BPA) epoxy resins in additional properties such as antibacterial properties and flame retardancy. Whether it is in the application of CCL, coatings, or composite materials, there are corresponding recommended bio-based epoxy resins.

Bio-based epoxy resin is a thermosetting resin with significant advantages in terms of resource renewability, environmental compatibility, and molecular structure characteristics, and has received extensive attention from domestic and foreign research in recent years. At present, the general-purpose bisphenol A (BPA) epoxy resin accounts for more than 85% of the global epoxy resin market, because its main raw material bisphenol A (BPA) is considered to be physiologically toxic, and has been banned from being used in food by many countries. , fields related to human contact. Therefore, we also provide bisphenol A (BPA) free bio-based epoxy resin, hoping to make a small contribution to health issues.

| Type | EEW (g/eq) | Viscosity (cps@25°C)*1 | Hy-Cl (ppm) | Bio-Carbon (%)*4 |

|---|---|---|---|---|

| Bisphenol A Epoxy (BPA) | 184–190 | 11,500–13,500 | <500 | 27 |

| Bisphenol F Epoxy (BPF) | 170–190 | 2,000–5,000 | <350 | 27 |

| Phenol Novolac Epoxy | 170–190 | H–K*2 | <350 | 27 |

| Acrylate Epoxy | 170–190 | 5,000–7,000*3 | <350 | 22 |

| Solid Type Epoxy | 250–270 | – | <500 | 55 |

*1 Viscosity, Brookfield Viscometer at 25℃

*2 Gardener Holdt Method, Butyl carbitol NV 60% solution

*3 Calculated

#bio epoxy #Carbon neutrality #Low carbon economy #Environmental protection #Health #CCL #Paint #Composite material

CONTACT US

Kelly Chemical Corporation

Electronics

TEL:(02)2762-1985 ext 11200

Online Message

Leave your contact information,

and we will get in touch with you soon.

Email Consultation

After receiving your email,

we will process it as soon as possible.send Email