Why do some materials shrink when heated? Unveiling the secrets of negative thermal expansion (NTE) materials

What is thermal expansion and contraction? Why do materials expand? And what are negative thermal expansion materials?

Basic Concepts of Thermal Expansion and Contraction

One of the most familiar physical phenomena in our daily lives is "thermal expansion and contraction": objects expand when heated and contract when cooled. For example, railway tracks expand in the summer heat and contract in the winter cold, so engineers leave expansion gaps when building bridges. Similarly, many young people today like to use wooden flooring for interior decoration, and installers also leave small gaps to prevent damage caused by thermal expansion and contraction.

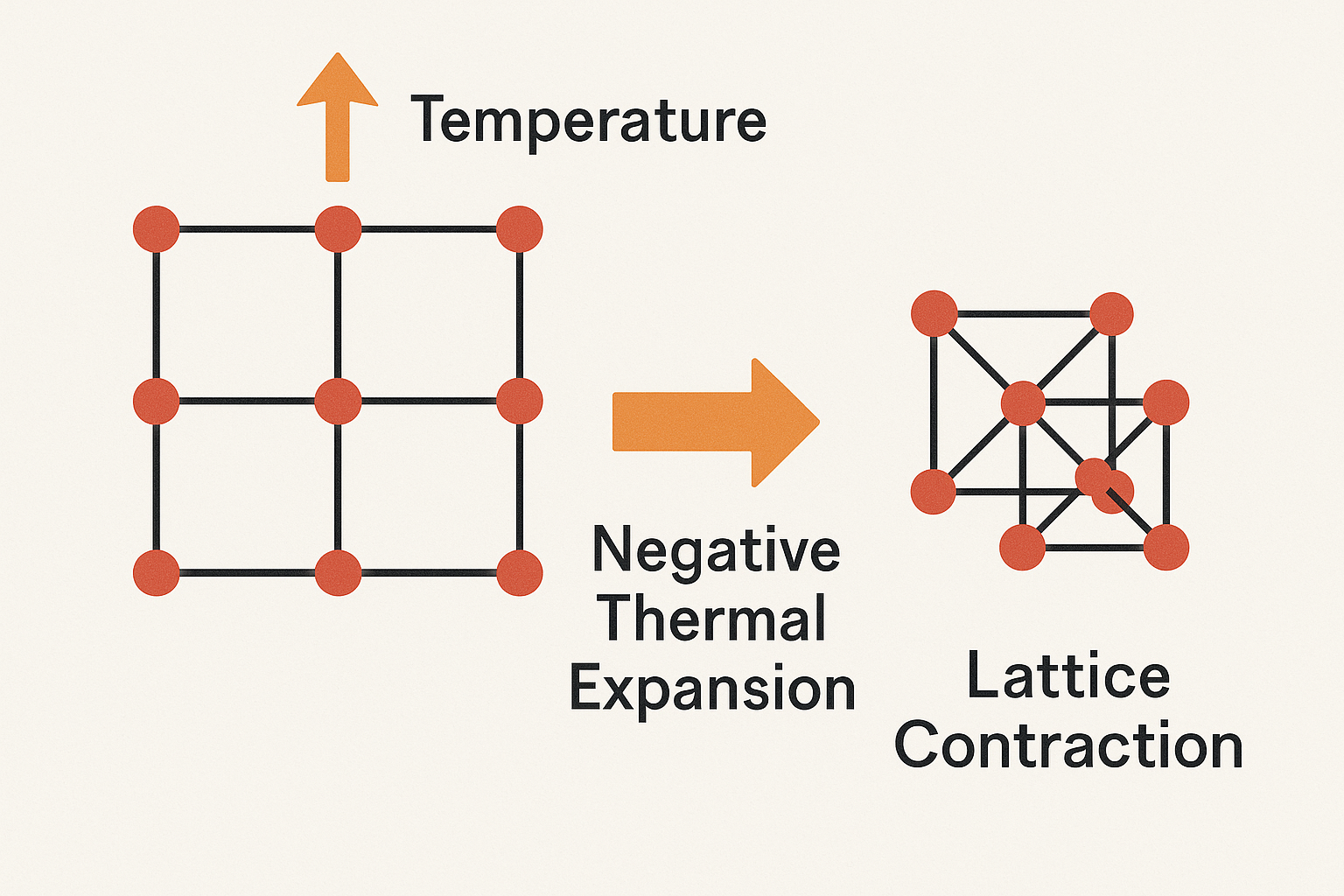

These phenomena occur because the atoms in a material absorb energy when heated, causing them to vibrate more vigorously. As a result, the distance between atoms in the crystal lattice increases, and the overall size of the material expands. However, not all materials follow this rule. Some materials actually shrink when heated; these are known as Negative Thermal Expansion (NTE) materials.

What are Negative Thermal Expansion (NTE) materials?

NTE materials are defined as materials that shrink when heated and expand when cooled within a specific temperature range. This counterintuitive behavior usually arises from the special arrangement of the material's crystal lattice or molecular structure, rather than from the atoms themselves "contracting in reverse."

- Lattice Rotation/Tilting Effect

- Certain ceramic materials, such as ZrW₂O₈ (zirconium tungstate)

- Atoms form "rotating units," and when heated, these units rotate within the lattice → causing the overall lattice to contract

- Molecular Framework Compression Effect

- Materials with porous molecular structures (e.g., MOFs) or certain metal oxides

- When heated, the internal spaces within the framework compress → resulting in a reduction in the material’s overall size

Common NTE Materials and Their Properties

| Material Type | Representative Compounds | CTE (×10⁻⁶/K) | Applications |

|---|---|---|---|

| Metal Oxides | ZrW₂O₈, HfW₂O₈ | -9 ~ -3 | Precision ceramics, optical substrates, chip packaging |

| Perovskites | ScF₃, ReO₃ | -10 ~ -5 | Precision mechanical parts, aerospace components |

| Metal-Organic Frameworks (MOFs) | Certain Cu-MOFs, Zr-MOFs | -20 ~ -5 | Gas adsorption, temperature-control materials |

What are the potential applications of Negative Thermal Expansion (NTE) materials?

- Semiconductors and Electronic Packaging

- Circuit boards and chips are sensitive to heat; mismatched thermal expansion can generate stress (especially in epoxy resins).

- Adding NTE materials in packaging → reduces thermal stress, extends component lifespan, and improves reliability.

- Precision Optics and Measurement Instruments

- Small dimensional changes in optical lenses or interferometers can affect accuracy.

- Using NTE materials for mounts or substrates → maintains stability.

- Aerospace and High-Precision Machinery

- Aircraft and satellite components are exposed to extreme temperature variations.

- NTE composites can control thermal expansion → reduce thermal stress and deformation.

- Medical and Chemical Equipment

- High-precision instruments and reactors require temperature stability.

- NTE materials reduce structural deformation, improving measurement accuracy.

Challenges and Limitations of NTE Materials

- Difficult Processing

- Many NTE materials are ceramics or complex crystals with low toughness and high brittleness.

- Special techniques are needed to process them into thin films or composites.

- High Cost

- Producing high-purity oxides or MOFs is expensive.

- Large-scale production is not yet widespread.

- Temperature Range Limitations

- Most NTE materials exhibit negative expansion only within a specific temperature range.

- Beyond this range, they behave like normal (positive) thermal expansion materials.

- Composite Control

- For applications, NTE materials often need to be combined with positive-expansion materials, such as spherical silica.

- The ratio and dispersion uniformity significantly affect performance.

Conclusion

Negative Thermal Expansion (NTE) materials challenge our intuitive understanding of thermal expansion and contraction. Although they are rare in nature, they hold tremendous potential and value in high-precision, electronics, aerospace, and optical applications. With advances in materials science and nanotechnology, we can expect NTE materials to see broader use—from micron-scale electronic packaging to large-scale aerospace structures—making these “the hotter, the smaller” materials a key factor in enhancing stability and reliability.

For more information about these materials, feel free to contact us for a discussion.

#Nanoparticles #NegativeCTE #NegativeThermalExpansion #NTE #WarpResistance #Nanotech

CONTACT US

Kelly Chemical Corporation

Electronics

TEL:(02)2762-1985 ext 11200

Online Message

Leave your contact information,

and we will get in touch with you soon.

Email Consultation

After receiving your email,

we will process it as soon as possible.send Email