Many people have heard of Bisphenol A (BPA), but have you heard of Bisphenol F (BPF)?

Many people might have known Bisphenol A (BPA), since it used to be the material of plastics and food containers. What about Bisphenol F (BPF)? This article will take you on a closer look.

(source: pexel.com)

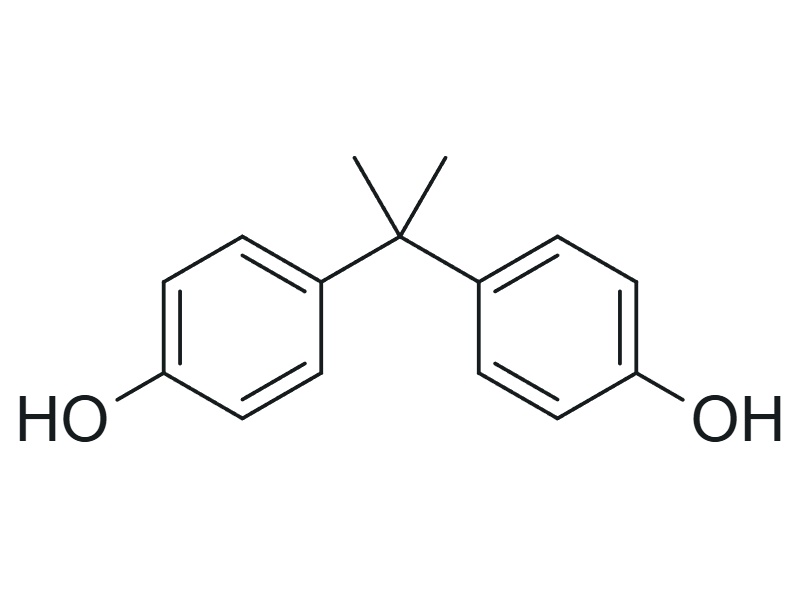

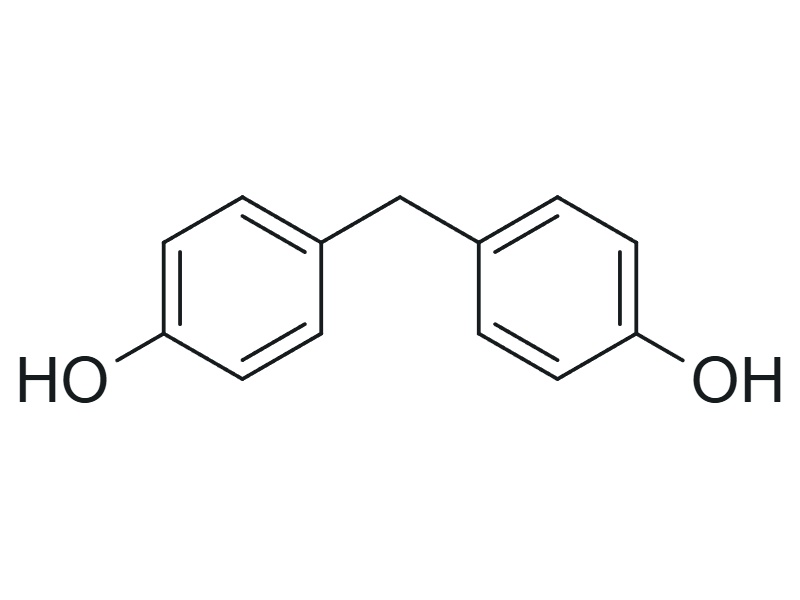

From the name alone, it's clear that Bisphenol F (BPF) and Bisphenol A (BPA) belong to the same family. Although their molecular structures are similar, BPF doesn't have two methyl groups on the bridge connecting the two phenol rings. As a result, BPA offers lower viscosity and greater stability, giving it superior performance in products.

The table below will help you understand their differences at a glance!

| Item | BPA (Bisphenol A) | BPF (Bisphenol F) |

|---|---|---|

| Chemical Structure |  |

|

| Structural Difference | Larger molecular size, more rigid structure | Smaller molecular size, more flexible structure |

| Viscosity | Higher, less favorable for flow | Lower viscosity, suitable for processes requiring high flowability |

| Common Applications | Plastic bottles, food containers, can linings, optical discs, etc. | Electronic encapsulation materials, industrial coatings, solvent-free epoxy resins |

| Processability | Moderate processability | Good processability, easily mixed with other epoxies to adjust performance |

| Mechanical Properties | Good structural strength after curing | High strength, high toughness, and electrical insulation after curing |

| Heat & Chemical Resistance | Good, but slightly less stable than BPF at high temperatures | More stable under high temperature and resistant to acids/bases |

| VOC Emission Impact | Commonly used in solvent-based products, higher VOC emissions | Mostly used in solvent-free applications, effectively reducing VOC emissions |

| Sustainability | Controversial, gradually being replaced | Plays an important role in promoting green materials development |

Picking a paint? Don't just pick a color—look at what it's made of!

Most of the traditional paints include Formaldehyde, Benzene, and Toluene. These volatile organic compounds (VOCs) are not only odorous but can also generate smoke over time, contributing to air pollution and potential health hazards.

UHS Clear Coat: None Odorous, Better Protection

Today's paint technology has come a long way. One example is the so-called Ultra-High Solids (UHS) paint, which has lower solvent content and reduced VOC emissions. This paint is thicker, allowing it to build up a strong protective layer with one stroke, making it very user-friendly. It saves time and performs better over the long term. From walls and furniture to car exteriors, UHS paints last longer and require less maintenance.

BPF Epoxy: Small Drops, Big Protection

So what's in these high-performance paints? One of the star ingredients is low-viscosity Bisphenol F (BPF) epoxy resin:

- Low viscosity: Easy to work with, brushes on smoothly, and penetrates surfaces effectively.

- High hardness: Becomes hard and scratch-resistant after solidfying, providing excellent wear resistance.

- Chemical resistance: Can withstand acids and bases, even in harsh chemical environments.

- High stability: Resistant to cracking, high temperatures, and humidity—perfectly suited for Taiwan's climate.

Low-viscosity BPF epoxy not only inherits the outstanding properties of Bisphenol F, but its low-viscosity formulation also creates a denser coating structure, resulting in superior overall protection.

The Unsung Hero Behind Electric Products

This resin is widely used in everyday electronics, from smartphones and televisions to LED lighting. Its low viscosity allows it to penetrate fine gaps and form a tight encapsulation around electronic components, providing effective protection against moisture and short circuits. In addition, its strong electrical insulation ensures stable device performance.

Applications include LED packaging, printed circuit boards, and automotive electronic parts. It can also be modified into thermally or electrically conductive adhesives, enhancing component bonding and improving heat dissipation.

It's more than just a material—it's a choice for a better life.

Coatings and electronic adhesives made with BPF not only deliver excellent performance but also help reduce air pollution. Thanks to its naturally low viscosity, less solvent is needed to adjust fluidity properties, which in turn significantly lowers VOC emissions—making it an important contributor to greener living.

In an era that emphasizes environmental responsibility, high-performance and low-emission materials such as BPF epoxy resin are gaining increasing attention. Not only does it help industries reduce pollution and extend product lifespan, but it also quietly safeguards the safety and stability of electronic devices in our daily lives. As both industrial demand and environmental responsibility grow, the importance of such materials will continue to rise significantly.

CONTACT US

Kelly Chemical Corporation

Electronics

TEL:(02)2762-1985 ext 11200

Online Message

Leave your contact information,

and we will get in touch with you soon.

Email Consultation

After receiving your email,

we will process it as soon as possible.send Email