Types of epoxy and hardener and three major applications

The wide variety of epoxy resin types is renowned for their excellent chemical resistance, heat resistance, and electrical insulation properties.

Matching them to various applications has become a focal point of interest for numerous developers.

The types of traditional epoxy resins

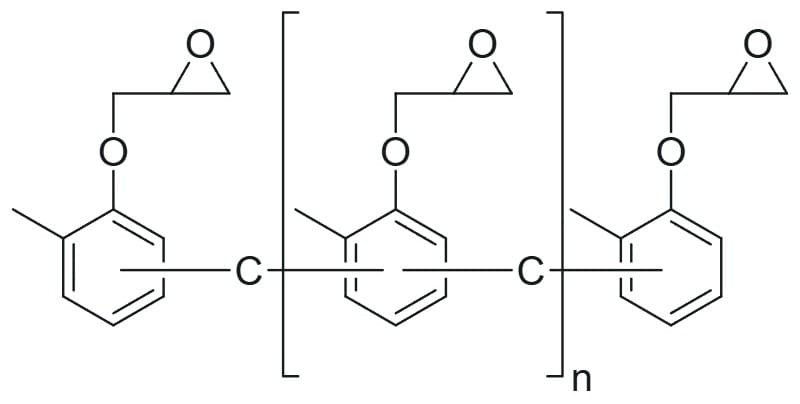

Bisphenol A Epoxy; DGEBA

Bisphenol A epoxy resin is a typical liquid epoxy resin formed by the condensation of bisphenol A and epichlorohydrin. It possesses excellent adhesion, chemical resistance, and heat resistance. Due to its exceptional properties, it finds wide applications in various fields, including:

1.Paints: Electrodeposition coatings, ambient cure coatings, transparent coatings, anti-corrosive coatings.

2.Electrical and electronic fields: Casting, impregnation, encapsulation, lamination, coatings for capacitors and resistors.

3.Civil engineering and construction: Cementitious concrete structures, waterproofing, anti-corrosion pavements, joint repair adhesives, grouting materials.

4.Adhesives: Adhesives for metals, glass, wood, and stone.

5.Fiber winding, fiberglass reinforced resin.

6.Stabilizers for polyvinyl chloride (PVC)

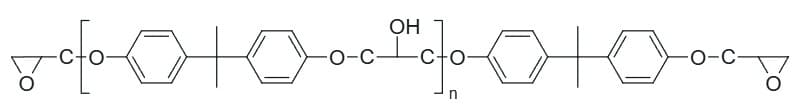

▲Schematic Representation of the Typical Structure of Bisphenol A Epoxy Resin

Bisphenol F Epoxy

Bisphenol F epoxy resin is synthesized from phenol and formaldehyde in an acidic environment, followed by condensation with epichlorohydrin. Structurally similar to bisphenol A epoxy, but lacks two methyl groups, bisphenol F exhibits lower viscosity, typically half or even lower compared to bisphenol A epoxy. This lower viscosity makes it more manageable and suitable for solvent-free coatings or casting materials, such as laminates, carbon fiber composites, etc. Blending bisphenol A and bisphenol F epoxies is a common practice to maintain low viscosity while achieving heat resistance and good electrical properties simultaneously. Its applications include:

1.Coatings: Ambient cure coatings, varnishes, anti-corrosive coatings, marine coatings, industrial coatings.

2.Electrical and electronic fields: Casting, impregnation, encapsulation, lamination, and insulation applications.

3.Civil engineering and construction: Cementitious concrete structures, waterproofing, anchoring adhesives, sealants, and grouting materials.

4.Adhesives: Adhesives for metals, glass, wood, stone.

5.Fiber winding, fiberglass, carbon fiber, fabric-reinforced resins.

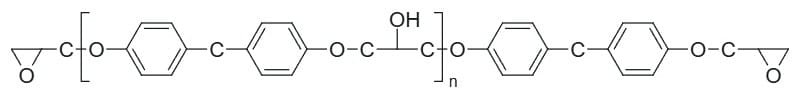

▲Schematic Representation of the Typical Structure of Bisphenol F Epoxy Resin

Brominated Epoxy

Due to its excellent heat resistance, flame retardancy, chemical resistance, and electrical properties, it is commonly used in flame retardant-related applications. For example, in laminates, during the manufacturing process of PCBs, temperatures may exceed 200°C. Therefore, the addition of halogenated high-heat-resistant epoxy resins has significant advantages. In addition to laminates, applications in transportation vehicles such as cars and aircraft, where high specifications and safety factors are considered, materials with flame retardant advantages can meet the requirements. The main applications are listed below, including flame-retardant durable laminates in EMC or FCCL laminates, molding materials, adhesives, and encapsulants. As well as flame retardants for ENPLA.

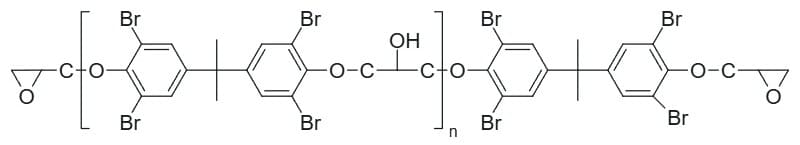

▲Schematic Representation of the Typical Structure of Brominated Epoxy Resin

▲Schematic Representation of the Typical Structure of Brominated Epoxy Resin

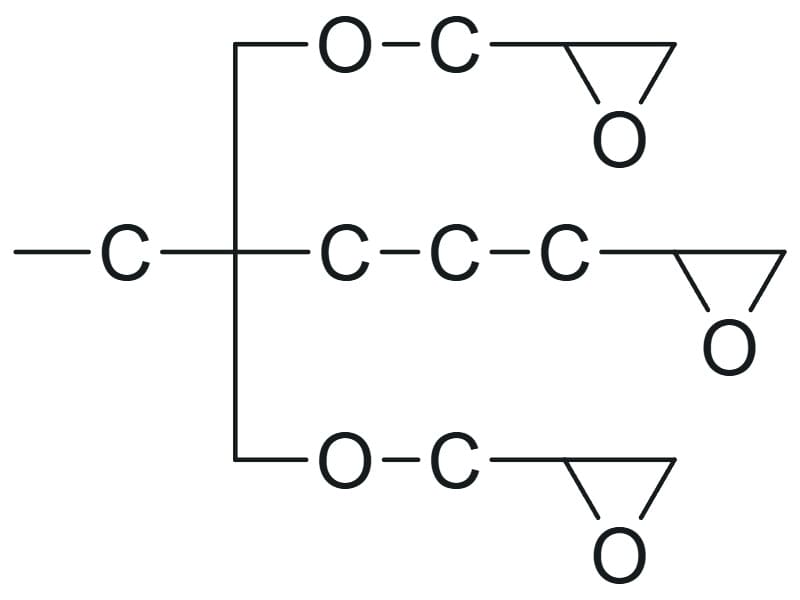

Phenolic Novolac Epoxy

Phenolic epoxy is synthesized from the reaction between epichlorohydrin and phenolic resin, featuring excellent chemical resistance, stability, and strength. However, compared to other materials, it exhibits relatively poor flexibility and is prone to fracture. Nevertheless, when its advantages are properly utilized, it finds applications in structural adhesives, laminates, composite materials (such as yachts, pipelines, automotive components), PCB solder resist ink (PSR Ink), and more.

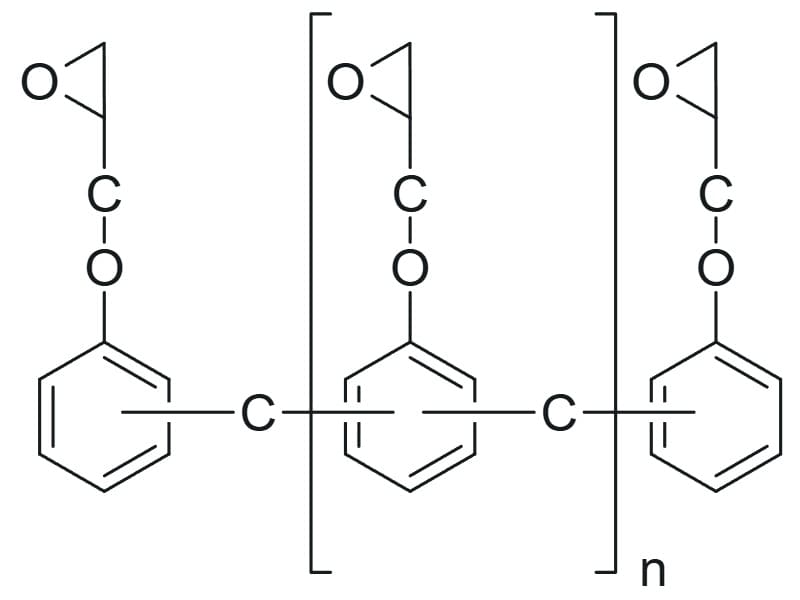

▲Schematic Representation of the Structure of Phenolic Epoxy Resin

o-Cresol Novolac Epoxy, CNE

This type of resin, synthesized from ortho-methylphenol and epichlorohydrin, features higher water resistance and lower viscosity compared to standard phenolic epoxy due to the additional methyl side chain. Additionally, its high heat resistance and chemical resistance make it suitable for applications requiring high Tg and low CTE material properties.

Its applications include powder coatings, PCB inks, and other applications requiring heat resistance, chemical resistance, and waterproofing. Moreover, it also demonstrates advantages in applications requiring good electrical properties, such as encapsulation materials (EMC), laminates, and underfill for electronic components.

▲Schematic Representation of the Structure of Ortho-Methylphenol Phenolic Epoxy Resin

2.Specialty epoxy resins

Tri-Functional Epoxy

Trimethylolpropanetriglycidylether, TMPTE

The special application epoxy resin is primarily a tri-functional active diluent, characterized by its significantly low viscosity. It is utilized to dilute and reduce the viscosity of resins. It has wide applicability, being compatible with most epoxy resins, and provides improved cross-linking. For example, mixing 20% of this diluent with 80% standard bisphenol A epoxy resin can be applied in applications requiring high adhesion capability.

▲Schematic representation of Trimethylolpropane Triacrylate

Silicone-modified trifunctional epoxy resin

The epoxy resin, modified with silicone, produces a highly adhesive material that significantly enhances bonding capabilities between dissimilar materials, such as organic and inorganic substrates, as well as glass and non-ferrous metals. It finds applications in coatings, paints, electronics, electrical engineering, fiberglass reinforcement, carbon fiber reinforcement, and more. The comparison between silicone-modified epoxy and standard bisphenol A epoxy below demonstrates excellent adhesion and shear strength on aluminum and glass substrates.

| Item | Material | Silicone-modified trifunctional epoxy resin | Standard bisphenol A epoxy resin |

|---|---|---|---|

| Coating adhesion test (% residual) | Iron substrate | 100 | 100 |

| Aluminum substrate | 100 | 37 | |

| Glass substrate | 100 | 20 | |

| Shear adhesive strength (Kgf/cm2) | 80.8 | 34.1 | |

![]()

▲Schematic Representation of the Structure of Silicone-Modified Trifunctional Epoxy Resin

Tera-Functional Epoxy

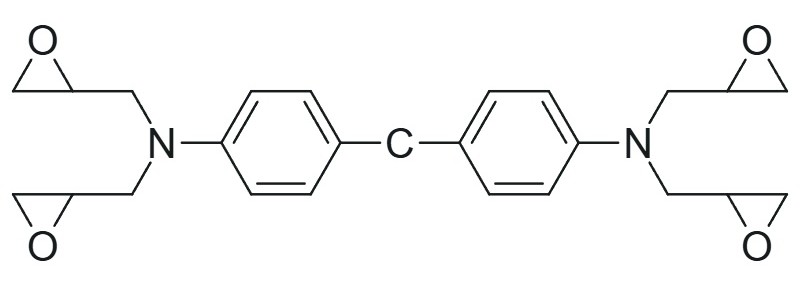

a.Tetraglycidyl 4,4′-diaminodiphenyl-methane, TGDDM

This type of resin is currently the most widely used tetrafunctional epoxy in applications. With four amino groups, it provides greater rigidity and excellent heat resistance, chemical resistance, and radiation resistance. Due to its high Tg characteristics (typically exceeding 230°C), it is commonly used as a material for aerospace industries, encapsulation, or applications requiring high-temperature adhesion.

▲Structure of TGDDM

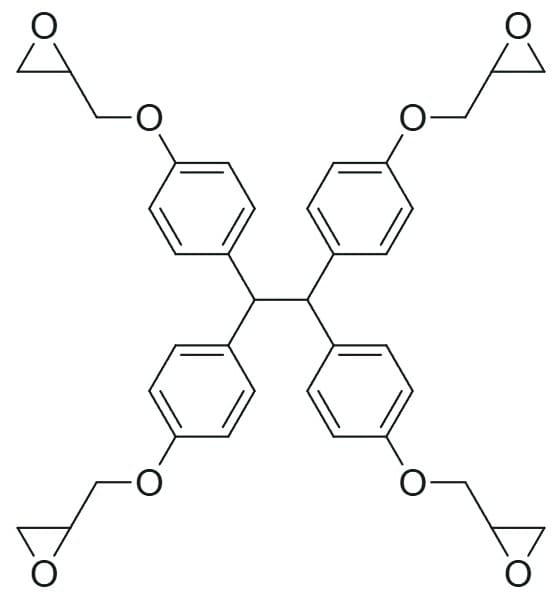

b.Glyoxal, oligomeric reaction products with 1-chloro-2,3-epoxypropane and phenol

Nitrogen-free tetrafunctional epoxy resin has recently garnered significant attention. This type is one of them. Although TGDDM is widely used, its nitrogen atoms lead to relatively high water absorption, reduced thermal stability, and closer epoxy group distances. To address these issues, this type of tetrafunctional epoxy resin avoids the use of nitrogen atoms and evenly distributes the epoxy groups as much as possible, which contributes to the integrity of the overall reaction.

▲Schematic representation of the structure of the oligomer produced from formaldehyde, 1-chloro-2,3-epoxypropane, and phenol

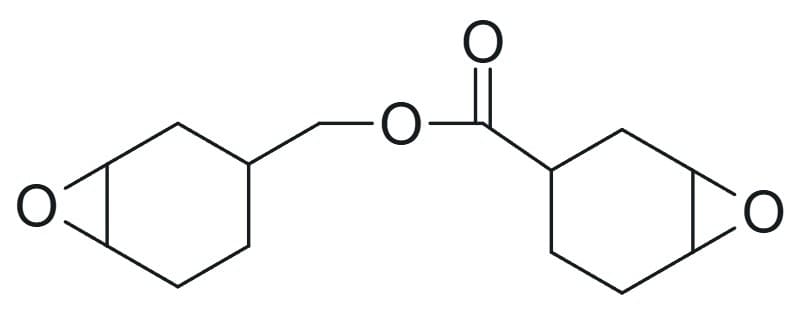

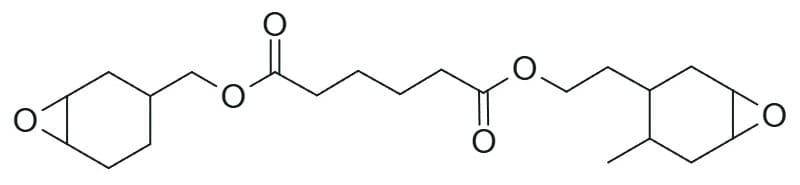

Cycloaliphatic Epoxy

Cycloaliphatic epoxy resin is a type of resin containing two double bonds in the cycloaliphatic group, obtained through oxidation reaction using peroxyacetic acid or organic peroxides. The two epoxy groups are attached to the cycloaliphatic ring, forming a tight structure after the reaction, which can achieve a lower coefficient of thermal expansion (Low CTE) at certain temperatures. Additionally, due to the absence of benzene rings, it exhibits excellent weather resistance and UV resistance, making it suitable for applications such as weather-resistant coatings, electronic insulation, potting, etc. Moreover, cycloaliphatic epoxy resin also possesses advantages such as transparency and low viscosity, making it suitable for solvent-free applications.

▲Schematic Representation of Standard Cycloaliphatic Epoxy Resin Structure

▲Schematic representation of long-chain cycloaliphatic epoxy resin structure

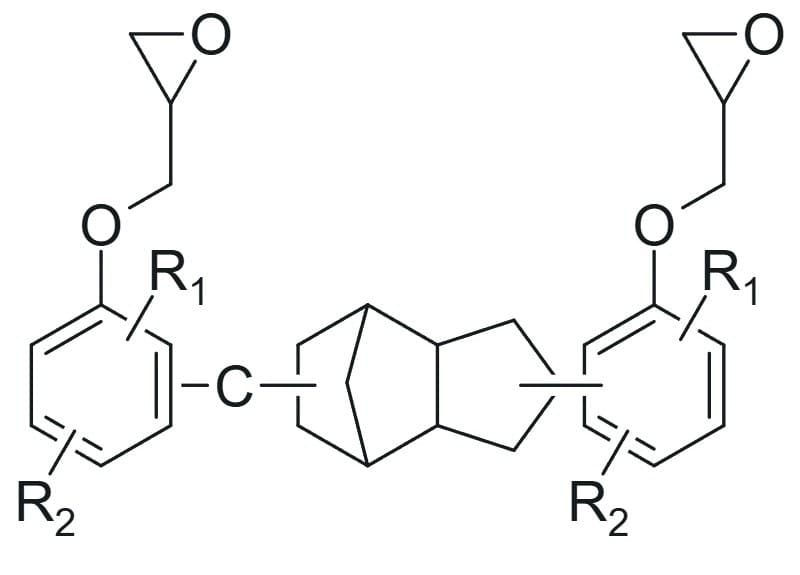

Dicyclopentdiene, DCPD

Derived from the polyaddition compound of dicyclopentadiene and 2,6-dimethylphenol. It possesses excellent low moisture absorption, low dielectric constant, considerable adhesion, as well as good heat and chemical resistance. Suitable for high-performance epoxy molding compounds (EMC) in semiconductor and laminate applications. The major advantage of using this product in semiconductor packaging is its significantly lower moisture absorption compared to previous generations of epoxy resins, such as cresol novolac epoxy (CNE) or biphenyl epoxy resins. In addition to molding materials, it can also be applied in electronic encapsulation materials, flexible materials, solder resist inks, and other fields.

▲Schematic representation of alkylphenol-based DCPD epoxy resin

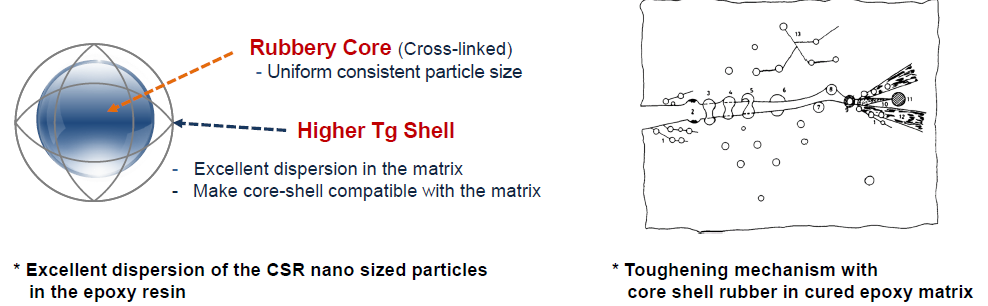

Core Shell Rubber Modified Epoxy

Designed for modification of epoxy resins with methyl methacrylate-butadiene-styrene (MBS) core-shell rubber. The design ratio of CSR is typically between 25-40%, exhibiting excellent flexibility, bonding strength, peel strength, impact resistance, fracture toughness, elastic modulus, shear, and tensile strength. Applications include reinforcement sealing for automotive body panels (BPR sealer), hem-flange adhesive, structural adhesives, aerospace industry, and adhesive for flooring and tiles.

▲Core-shell structure illustration in toughened epoxy resin

Further Reading:(Toughened epoxy resin-CSR core-shell technology to solves the problem of brittleness!!

Summary of Epoxy Resin Properties and Applications

| Epoxy Resin Type | Physical Parameters | Properties* | Application | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Viscosity (cps) |

Free Chlorine (ppm) |

Total Chlorine (ppm) |

Weather Resistance | Heat Resistance | Chemical Resistance | Low Moisture Absorption | Tg | ||

| Low Chlorine Bisphenol A | 3000–5000 | <50 | <200 | - | ++ | ++ | - | - | Chlorine content formulation adjustment |

| Low Chlorine Bisphenol F | 1000–2000 | <200 | <700 | - | ++ | ++ | - | - | Chlorine content and viscosity adjustment |

| Brominated Epoxy | Solid | <500 | - | - | ++ | - | - | - | Flame retardant formulation adjustment |

| Phenolic Varnish | 3000–4500 | <350 | - | - | ++ | ++ | + | ++ | Chemical resistance formulation adjustment |

| Orthocresol Novolac | 10000–20000 | <1000 | - | - | +++ | +++ | + | ++ | Chemical resistance formulation adjustment |

| Triglycidyl Methane | 4000–6000 | <800 | - | - | + | + | - | - | Viscosity reduction, adhesion improvement |

| Trifunctional Silicone Modified | 9000–150000 | <500 | - | - | ++ | ++ | - | - | Adhesion for dissimilar materials |

| Tetrafunctional TGDDM | Solid | - | - | - | ++ | ++ | - | +++ | High Tg formulation adjustment |

| Tetrafunctional Aldehyde | Solid | <3000 | - | - | ++ | ++ | ++ | +++ | Low moisture absorption, high heat resistance applications |

| Cycloaliphatic | 200–400 | - | - | ++ | ++ | ++ | ++ | - | Solvent-free, transparent dilution applications |

| Bicyclopentadiene | Solid | <200 | <1000 | ++ | ++ | ++ | +++ | ++ | Encapsulation and high heat resistance applications |

| CSR Flexible | 20000–200000 | - | - | - | ++ | ++ | - | - | Toughening, impact-resistant design |

*+ The more, the better the effectiveness of this characteristic

Classification of Epoxy Curing Agents

Products formed by epoxy typically result from the reaction of two components, A and B. Component A usually represents the epoxy resin, while component B represents the curing agent. Since the curing agent also accounts for a significant portion of the formulation, its role is crucial in determining properties such as chemical resistance, heat resistance, and mechanical strength of the final product. This underscores the importance of curing agents in influencing the ultimate properties. Below are several common types of curing agents along with their characteristics and suitable applications.

| Type | Curing Agent | Reaction Temperature | Temperature Range | Heat Resistance | Chemical Resistance | Low Moisture Absorption | Curing Speed | Features |

|---|---|---|---|---|---|---|---|---|

| Dicyandiamide | Dicyandiamide (DICY) | 120–150°C | Medium | ++ | ++ | + | - | High standalone reaction temperature, usually combined with imidazole promoters. Commonly used in latent formulations. |

| Aliphatic Amine | Diethylenetriamine (DETA) Triethylenetetramine (TETA) |

80–120°C | Room / Low-Medium | ++ | ++ | + | ++ | Common epoxy curing agents with good heat and chemical resistance, suitable for casting, coatings, and cables. |

| Imidazole | Imidazole (Imidazole) 2-MI 2-PZ |

80–120°C | Medium | + | + | + | +++ | Fast reaction speed |

| Anhydride | 4MHHPA THPA |

>150°C | High | ++ | ++ | - | ++ | High curing temperature, good electrical and heat resistance, slightly lower moisture resistance. |

| Aromatic Amine | DDS DDM PACM |

>150°C | High | ++ | ++ | ++ | - | Excellent heat and chemical resistance, low moisture absorption, high Tg, commonly used in high-performance encapsulation. |

| Phenolic | Novolac Resin | >150°C | High | ++ | ++ | + | - | Excellent heat and chemical resistance, commonly used in powder coating applications. |

Examples of epoxy resin and curing agent combinations

Molding Compound

| Item | Value | |

|---|---|---|

| Formulation (phr) | Standard solid epoxy resin | 100 |

| DDM | 9.6 | |

| Calcium stearate | 3 | |

| Silicon Dioxide | 250 | |

| Reaction condition | Mixing (°C/min) | 25–57/5 |

| Aging (min at 80°C) | 43 | |

| Physical properties | H.D.T (°C) | 105.5 |

| Barcol hardness | 52 | |

|

Water absorption (1 hr boiling, wt.%) |

0.212 | |

| Flexural strength (kg/mm²) | 12.7 | |

| Volume resistivity (ohm·cm) | 1.7×1014 | |

*Potting condition: Pressure 100-200 kg/cm2 at 150°C for 10 minutes

Paint Application Reference Formulation Ingredients and Physical Properties

| Item | Value | ||

|---|---|---|---|

| Formulation (wt.%) | Phenolic varnish epoxy resin | 32 | |

| Titanium dioxide | 18 | ||

| Talc | 20 | ||

| Diluent | 11 | ||

| Additives | 3 | ||

| Cycloaliphatic amine hardener | 16 | ||

| Reaction Conditions | Mixing ratio A:B (wt.%) | 84:16 | |

| Pigment volume concentration (%) | 30 | ||

| Volume solids content (%) | 65 | ||

| Curing conditions | 25°C for 7 days | ||

| Physical and Chemical Properties | Pot life | 4 hr 30 min | |

| Drying time | Touch dry | 2 hr | |

| Fully dry | 7 hr 30 min | ||

| Shore hardness | 77 | ||

| Abrasion resistance (mg/weight loss) | 61 | ||

| Chemical Resistance (25°C for 14 days) | 50% NaOH | No foaming, softening, swelling, loss of adhesion | |

| Phenol | |||

| Tetrahydrofuran | |||

| Methanol | |||

Reference formulation ingredients and physical properties of potting materials

| Item | Value | ||

|---|---|---|---|

| Formulation (wt.%) | Ortho-cresol novolac epoxy resin | 16 | |

| Silica micro powder | 70 | ||

| Phenol-formaldehyde resin | 8.5 | ||

| TPP | 0.3 | ||

| Toughening agent | 2 | ||

| Other additives | 3.2 | ||

| Total | 100 | ||

| Physical Properties | Vortex flow length (inch) | 33.5 | |

| Gel time (sec) | 26.9 | ||

| Resin exudation (mm) | 1.43 | ||

| Hardness | 88 | ||

| Flexural strength (Kgf/mm²) | 14.5 | ||

| Flexural modulus (Kgf/mm²) | 1,388 | ||

| Purity | Cl⁻ (ppm) | 4.5 | |

| Fe⁺ (ppm) | 2.2 | ||

| Na⁺ (ppm) | 3.3 | ||

Reference formulation ingredients and physical properties applied to laminated panels

| Item | Ratio | |

|---|---|---|

| Formulation | o-Cresol Novolac Epoxy Resin | 100 |

| MEK | 25 | |

| DDS | – | |

| BF3MEA | 63.6 | |

| BDMA | 1.1 | |

| Diluent | – | |

| Reaction Conditions | B-Stage (°C/min) | 130/10 |

| Press (Kg/cm²/°C/min) | 15/170/120 | |

| Physical Properties | Barcol Hardness | 70 |

| Flexural Strength (Kg/mm²) | 54.2 | |

| Tensile Strength (Kg/mm²) | 39.5 | |

| Volume resistivity (ohm-cm) | 1.59x1016 | |

| Resin content (%) | 36.7 | |

CONTACT US

Kelly Chemical Corporation

Electronics

TEL:(02)2762-1985 ext 11200

Online Message

Leave your contact information,

and we will get in touch with you soon.

Email Consultation

After receiving your email,

we will process it as soon as possible.send Email