Low chlorine epoxy resin : Characteristics commonly used in product development in the electronic and electrical fields!!

Low chlorine epoxy resin, low CTE epoxy resin, and solvent-free epoxy resin are now very popular~!!

The rapid iteration of electronic products has raised the specifications of peripheral materials to a high standard~!

Epoxy resin is often used in a wide range of electronic and electrical fields. In the bonding, coating, molding materials, underfills, and circuit board materials of semiconductors and printed circuit boards. In recent years, due to the miniaturization and high performance of electronic and electrical related products, there has been a demand for special resins with higher purity and uniqueness in product design. For example, if one or more excellent properties are required in terms of mechanical properties, adhesion, expansion and contraction, insulation, anti-corrosion, dielectric constant and other properties, low-chlorine epoxy resin is produced under this background. Since electronic products need to undergo a series of more stringent tests, in high temperature and high humidity environments, the chlorine in epoxy resin is very likely to cause corrosion of electronic circuits, leading to a decrease in reliability. Therefore, specifications with high purity, few impurities, and low chlorine content have gradually become the mainstream specifications of epoxy resins in the electronic field.

▲Low chlorine epoxy resin has gradually become the basic requirement for many applications

Ionic chlorine and organic chlorine in epoxy resin

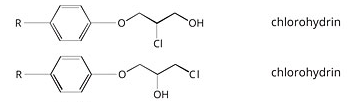

The ionic chlorine produced during the synthesis process, which is produced by the reaction of bisphenol with epichlorohydrin, can be removed to low ppm by a water washing process. Chlorine-containing organic compounds produced as by-products cannot be removed by water treatment. In some cases, chlorohydrins can dehydrochloride and release inorganic chlorides in the coating. This can be detrimental to corrosion resistance. For example, cathodic electrodeposition coatings generate such inorganic chlorides during the manufacturing process. The high concentrations of chloride produced can attack the anodes in the electrolyzer, requiring premature replacement.

Hydrolyzable Chloride

Since the chloroether alcohol is not completely dehydrohalogenated, there is still residual chlorine, which is the so-called ionic chlorine. This residual chlorine will cause corrosive problems after the back-end resin is cured, causing a decrease in reliability and lowering the resin product. applicability. This type of ionic chlorine can be reduced to ppm level through water washing process.

▲The form of ionic chlorine

(Source: Watkins M. Troubleshooting High-Performance Epoxy Systems, Dixie Chemical, presented at the Thermoset Resin Formulators Association Annual Meeting, Niagara Falls, Ontario, September 12-13, 2011)

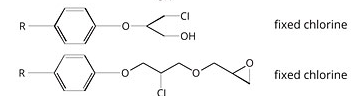

Organic Chlorine Compound

During the manufacturing process of epoxy resin, in addition to the production of ionic chlorine, a certain amount of organic chlorine compounds will also be produced, which will make about 0.5-1% of the total chlorine content in the overall epoxy resin come from this. This organic chlorine will be converted into ionic chlorine under specific temperature and humidity, causing corrosion of contact components. This part of the chlorine-containing organic matter cannot be removed through the water washing process and must be reduced through multiple crystallization purifications of the solvent.

▲Combined chloride form

(Source: Watkins M. Troubleshooting High-Performance Epoxy Systems, Dixie Chemical, presented at the Thermoset Resin Formulators Association Annual Meeting, Niagara Falls, Ontario, September 12-13, 2011)

Method for detecting ionic chlorine in epoxy resin ASTM D1726 (Method B)

Methanol, toluene and acetone solvents were added and then refluxed at 120°C for 15 minutes. Dilute with acetone and add glacial acetic acid. Finally, silver sulfate is used as a titration solution to analyze the ionic chlorine in the epoxy resin.

Commercial low chlorine epoxy resin types

BPA type low chlorine epoxy resin

It is a bisphenol A-type liquid epoxy resin with low viscosity and extremely low chlorine content. It is particularly suitable for achieving better performance in the electronic and electrical fields. Suitable application fields include sealants in the electronics industry and LED/LCD transparent film plastics. Suitable curing agents include polyamide resins, aromatic polyamines, aliphatic polyamines and acid anhydride compounds.

Hy-Cl (ppm): <50

Total-Cl (ppm): <200

BPF type low chlorine epoxy resin

It is bisphenol F type liquid epoxy resin. Compared with the same type of epoxy resin, it has the same advantages but also has a relatively low chlorine content. It has better performance in the electronic and electrical field where specifications are gradually becoming stricter. In addition, the low viscosity feature brings more advantages and convenience in operation. The applicable fields include the bonding of semiconductors and PCBs, mold materials, conductive adhesives, and sealants. High transparency molding materials for LEDs and displays.

Hy-Cl (ppm): <50

Total-Cl (ppm): <200

BPA/BPF low chlorine epoxy resin

It is a non-crystalline liquid epoxy resin of bisphenol A/F. Compared with ordinary epoxy resins of the same type, it has the same mechanical properties, but at the same time has relatively less chlorine content, which can show better product performance in the electronic and electrical fields. The amorphous nature makes this epoxy resin more widely used. Suitable application fields include conductive adhesives and sealants for semiconductors and PCBs. Transparent film plastics and film materials for displays.

Hy-Cl (ppm): <200

Total-Cl (ppm): <700

In addition to their advantages in corrosion protection, low-chlorine epoxy resins also exhibit excellent mechanical properties, adhesion and insulation properties, making them ideal for demanding applications. Especially in the packaging and molding applications of semiconductors, printed circuit boards (PCBs) and other electronic components, low-chlorine epoxy resins, with their low viscosity and stable properties, can not only meet the needs of miniaturization, but also ensure that the products are Reliability over long periods of use.

The development of low-chlorine epoxy resin not only responds to the high standards of material performance required by current electronic products, but also provides strong support for higher-end and more complex application scenarios in the future. With the continuous advancement of technology and the growth of market demand, the application prospects of low-chlorine epoxy resin will become broader and become an important cornerstone to promote the development of the electronic industry.

CONTACT US

Kelly Chemical Corporation

Electronics

TEL:(02)2762-1985 ext 11200

Online Message

Leave your contact information,

and we will get in touch with you soon.

Email Consultation

After receiving your email,

we will process it as soon as possible.send Email