What are the suitable materials for Low K product development? Hollow glass beads meet your needs!!

Hollow glass beads, with extremely low Dk and Df values. At 10 GHz, Dk is only around 1.6, and Df is approximately 0.005!!

Kelly Chemical provides various specifications of hollow glass microsphere materials, effectively enhancing the added value of products.

In the era of rapid development in the Internet of Things and technology, 5G communication has quietly entered our lives. As electronic components become smaller and chip circuits more refined, the trend increases the capacitance between electrical wiring, potentially causing signal delays. Additionally, the application of 5G further drives high-frequency wave communication. High-frequency radio waves are prone to converting to thermal energy, leading to potential transmission losses that can affect chip yield. To address these issues, using materials with a low dielectric constant (Low K) is an excellent solution.

The choice of materials is a crucial factor in determining the quality of network speed.

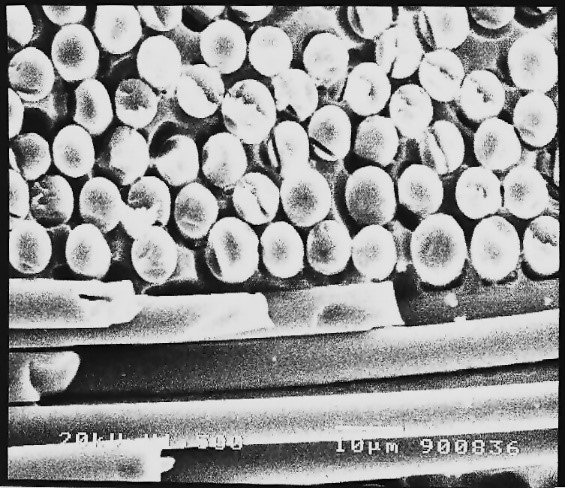

Hollow glass beads are a forward-looking new material with a micrometer-level smooth surface, primarily composed of borosilicate glass. Under a microscope, they appear as transparent hollow spheres with low density, high strength, high temperature resistance, acid and alkali resistance, low thermal conductivity, and electrical insulation. They also possess various properties such as good flowability, chemical stability, and dimensional stability.

Hollow glass beads have three key features: low thermal expansion coefficient, low density, and low dielectric constant (Low K), making them a star filler in the 5G generation. They can be applied in CCL copper foil substrate resins, antenna covers, phone cases, PC housings, etc., for products requiring lightweight and excellent signal transmission.

▲Hollow glass microspheres in CCL resin schematic diagram (as above)

For example:

a. Low Dk engineering plastics

5G communication utilizes millimeter waves with short wavelengths, poor diffraction capabilities, and significant attenuation during propagation. Reducing the dielectric constant of materials can enhance signal transmission speed, reduce latency, and minimize losses.

The unique hollow and thin-walled structure of hollow glass microspheres effectively enhances the dielectric performance of 5G materials. PP+ modified plastic with hollow glass beads achieves a low Dk value ranging from 2.2 to 2.4.

Real-world applications include 5G base stations, antenna system casings and coatings, and protective materials for smart terminals.

Testing Data:"

|

Dk |

Df |

Notch Impact KJ/m2 |

Tensile Strength MPa |

Flexural Strength MPa |

Flexural Modulus MPa |

Density g/cm3 |

|

|---|---|---|---|---|---|---|---|

| PC | 2.833 | 0.00558 | 18.04 | 42.428 | 69.59 | 2288.12 | 1.206 |

| PP+GF10+HGB8 | 2.258 | 0.00152 | 18.42 | 36.12 | 48.36 | 2082 | 0.914 |

b. CCL Copper Clad Laminate

Hollow glass beads offer cost advantages!!

Current Situation:

- Metal materials are heavy, leading to shading and interference.

- Dielectric materials such as Liquid Crystal Polymer (LCP) and PTFE possess good properties like flexibility and sealing but come at a high cost.

Replacement Solution: Utilize (PP+Glass Fiber+Hollow Glass Microspheres) modified plastic as a substitute for LCP and PTFE.

Benefits:

- Lower dielectric constant.

- Excellent material stability, meeting requirements for low warping and high sealing.

- Significant reduction in costs."

Recommended Products-

| Product Name |

True Density g/cm3 |

Bulk Density g/cm3 |

Compressive Strength MPa/Psi |

D50 (µm) |

D90 (µm) |

Application |

|---|---|---|---|---|---|---|

| HM10 | 1.40-1.60 | 0.60-0.62 | 192.5/28,000 | 5 | 10 | 5g plastic, high-frequency high-speed CCL, Low K film material |

| HS46 | 0.44-0.48 | 0.22-0.25 | 110/16,000 | 20 | 30 | 5g plastic, high-frequency high-speed CCL, Low K film material |

#Hollow glass beads #Low K #Low dielectric coefficient material #Copper Clad Laminate CCL #5G #Low thermal expansion coefficient #High fluidity #CCL #High frequency and high speed

CONTACT US

Kelly Chemical Corporation

Electronics

TEL:(02)2762-1985 ext 11200

Online Message

Leave your contact information,

and we will get in touch with you soon.

Email Consultation

After receiving your email,

we will process it as soon as possible.send Email