What is the principle of AR film anti-reflection ? It can effectively improve solar power generation efficiency, driving safety and reduce energy consumption

Why is anti-reflection and increased light transmittance needed? What are the benefits after improvement?

Kelly Chemical provides various high-quality, high-spec hollow silica powders/dispersions to assist you in developing trend products.

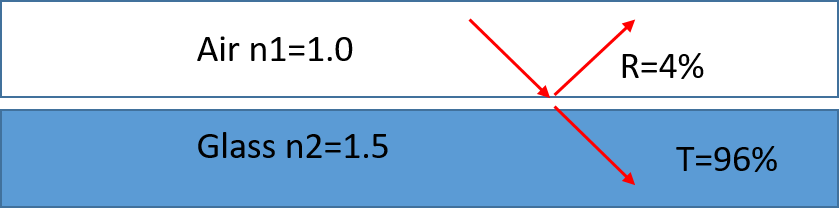

When light enters glass from air, due to the difference in refractive indices between the two, some of the incident light is reflected at the interface. Taking glass as an example, approximately 4.0% of incident light is reflected at each interface when light enters glass from air (n1=1) to glass (n2=1.5). This 4% reflected light is enough to bring many negative impacts to humans. Conversely, even a slight increase of 0.1% in light transmittance can bring significant benefits to humans! For solar panel manufacturers, high light transmittance means high power generation efficiency; glare from car windshields affects driving safety; reflections on glass storefronts affect aesthetics; reflections on mobile phone screens affect readability, and so on, all attributable to light reflection.

How to reduce light reflection between two interfaces? The simplest way is to add a coating layer between them. The refractive index of this coating layer is between 1.0 and 1.5. This way, the reflected light at the air/coating and coating/glass interfaces interferes and cancels out, thereby reducing reflection and increasing light transmittance. Organic resins have their limits in refractive index, so inorganic materials become the best choice. Magnesium fluoride (MgF2) has a refractive index of 1.38, making it one of the ideal materials, but its refractive index is still not low enough, and its price is extremely high. Solid silica dioxide has a refractive index of 1.5, which is not ideal for low refractive materials, but if pores can be introduced into solid silica dioxide materials, the refractive index can be effectively reduced. For example, if solid silica dioxide has a porosity of 50%, then the refractive index of this hollow silica dioxide particle is 1.5 * 50% + 1 * 50% = 1.25, much lower than magnesium fluoride, and the price is competitive, making it the most eye-catching low refractive material at present.

(Extended Reading:Nano hollow silica(SiO2)-5G Low K, heat insulation, low reflection AR film material)

The following are some applications of trending low reflection coatings-

- Mobile phone AR (Anti Reflection) film - combines high definition with solving glare problems.

- Automotive AR (Anti Reflection) film - reduces light reflection to improve safety.

- Micro LED - when used with high refractive materials, it can achieve high brightness and low glare, greatly improving clarity.

- Semiconductor photoresist AR (Anti Reflection) coating - during exposure, photoresist often reflects on the surface of silicon chips or metal layers, causing deviations in pattern replication; or interference occurs between transmitted light and reflected light, causing stripes in the exposure area, resulting in wave-like irregularities on the sidewalls after development. Therefore, anti-reflection coatings are a common way to solve these problems.

- Solar cell AR (Anti Reflection) film - reduces light reflection to improve power generation efficiency.

#LowReflectionMaterials #Anti-Reflection #TransparencyEnhancement #ARFilm #Nanomaterials

CONTACT US

Kelly Chemical Corporation

Electronics

TEL:(02)2762-1985 ext 11200

Online Message

Leave your contact information,

and we will get in touch with you soon.

Email Consultation

After receiving your email,

we will process it as soon as possible.send Email