High-purity spherical nano/submicron Alumina, adding a small amount can greatly reduce the sintering temperature and improve thermal conductivity!!

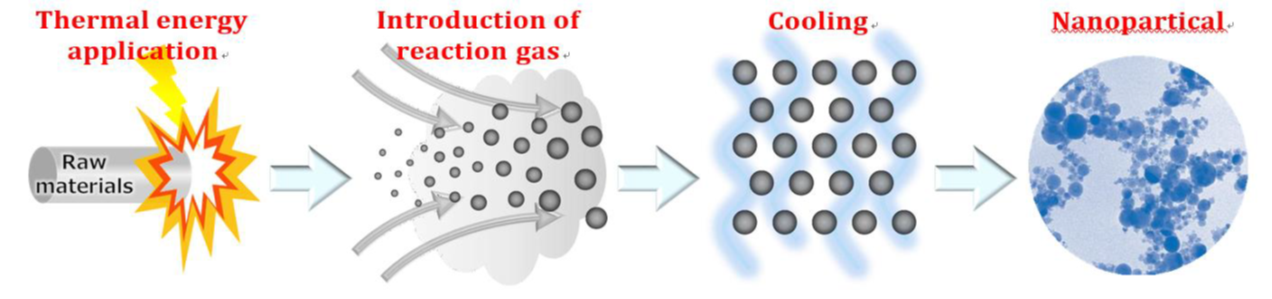

The "Physical Vapor Synthesis (PVS)" method is used to produce ultrafine particle materials, which is a gas-phase synthesis method. Firstly, plasma energy is applied to the raw material (metal) to melt and vaporize the metal. Then, oxygen is introduced as the reaction gas to form metal oxides. Once the metal oxide particles are formed, they are immediately cooled to suppress particle growth, thereby producing nanoscale ultrafine particle materials.

Key advantages-

・Small particle size (average particle size: 20-50nm)

・High crystallinity

・Good dispersibility (overcoming the drawbacks of nanomaterials)

・Good flowability (spherical)

・Extremely low aggregation

・Increased filling ratio

・High purity

Introduction to Nano Alumina-

Compared with other materials, alumina has many unique and excellent properties, such as high melting point (2,015°C), high strength, high chemical stability, dielectric properties, good electrical insulation, and high hardness (Mohs hardness 9), good wear resistance, and low cost. The special optical and electrical properties of nano-alumina, high magnetic resistance phenomenon, nonlinear resistance phenomenon, high strength and toughness, and stability even at high temperatures, combined with the small size effect, surface/interface effect, quantum size effect, and macroscopic quantum tunneling effect common to nanomaterials, make it widely used in catalysis, light filtering, light absorption, medicine, magnetic media, ceramics, and new materials.

1.Application in ceramics: Precision ceramics made from nano-alumina powders have similar plasticity and toughness to metals, lightweight, and greatly improved strength. Adding a small amount of micron or nano-alumina to conventional ceramic substrates can significantly improve the mechanical properties of the material, improve the toughness of ceramics, and reduce sintering temperature.

2.Medical applications: Ultrafine alumina powder bioceramics are basically non-corrosive in physiological environments, have good structural compatibility, and new tissue grows on the coherent pores on the porous ceramic surface, with higher bonding strength between the tissue and the body, and have high strength, low friction coefficient, and low wear rate. Therefore, it is widely used in clinical applications such as load-bearing artificial bones, dental implants, and drug release carriers.

3.Protective applications: As a surface protective layer material, spraying nano-alumina particles on the surface of metals, ceramics, plastics, and other materials can significantly improve surface strength, wear resistance, and corrosion resistance.

4.Optical applications: Nano-alumina can absorb ultraviolet light and generate light waves related to particle size under excitation of certain wavelength light. Alumina can be sintered into transparent ceramics, used as materials for high-pressure sodium lamp tubes; used as protective coatings for fluorescent powder layers in compact fluorescent lamps; and used as luminescent materials for fluorescent lamp tubes with rare earth fluorescent powders to improve lamp life. In addition, nano-alumina porous membranes have infrared absorption properties and can be made into stealth materials for military applications; they can be used as UV shielding materials and cosmetic additives due to their absorption effect on 80nm ultraviolet light.

5.Catalyst applications: Nano-alumina has an important catalytic function as a catalyst and its carrier in its new uses. Nano-powders have a large specific surface area, and the performance of catalysts and catalyst carriers made from them exceeds that of ordinary catalytic materials by several times.

6.Electronic industry applications: Nano-alumina has a huge surface and interface and is sensitive to changes in external humidity, and it is stable, making it an ideal moisture-sensitive sensor and hygrometer material. At the same time, it has good electrical insulation, chemical durability, heat resistance, strong radiation resistance, high dielectric constant, and uniform surface, and can be used as a substrate material for semiconductors and large-scale integrated circuits, widely used in microelectronics, electronics, and information industries.

7.Thermal conductivity applications: Spherical alumina has a large filling amount. Its maximum addition in liquid silicone gel can increase the thermal conductivity of the resulting product by about twice, and the thermal conductivity effect can be increased by mixing nano-spherical alumina with micron-level alumina, which can be used in CCL (soft board/hard board), MCPCB, thermal plastic, epoxy resin thermal filling material, silicone thermal paste, thermal silicone filling material, silicone thermal pad, and thermal sealing gel.

Nano alumina Nano Al2O3

Applications and expected results-

・MLCC dielectric and internal electrode additives

・Ceramic sintering aids to improve mechanical and dielectric properties and reduce sintering temperature

・Heat dissipation fillers for bottom encapsulation and heat dissipation films

・Polishing agent

・Improving scratch resistance of paints and coatings (hard coating)

・Improving adhesion to substrates

・Improving thermal radiation

Manufacturing nano-spherical alumina has a high threshold. We provide high-quality products from Japan and offer consultations on custom dispersion. If you are interested in our products, please feel free to contact us anytime.

CONTACT US

Kelly Chemical Corporation

Electronics

TEL:(02)2762-1985 ext 11200

Online Message

Leave your contact information,

and we will get in touch with you soon.

Email Consultation

After receiving your email,

we will process it as soon as possible.send Email