Hollow Glass Microspheres, the magical application of thermal insulation coatings~!!

Hollow Glass Microspheres: A Key Material in Mitigating Global Warming and Enhancing Product Value.

Through practical verification by customers, the application of hollow glass microspheres in thermal insulation coatings has demonstrated comparable low thermal conductivity coefficients to those of leading foreign competitors. During summer, these coatings can effectively block outdoor heat, reducing indoor temperatures and decreasing the need for air conditioning, thereby mitigating greenhouse gas emissions.

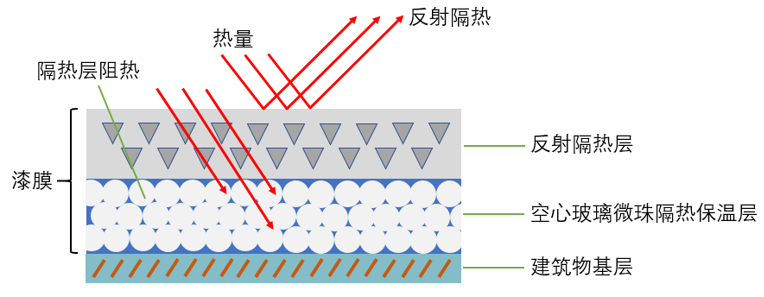

▲ Diagram of house exterior wall (as above)

Hollow glass microspheres are pioneering materials with micron-level smooth surfaces, primarily composed of borosilicate glass. Under the microscope, they appear as transparent, hollow spheres with properties including low density, high strength, high temperature resistance, acid and alkali resistance, low thermal conductivity, electrical insulation, good flowability, chemical stability, and dimensional stability.

Various methods exist for insulating the exteriors of houses, commonly involving the use of insulating bricks or roof coatings. However, insulating bricks are best applied during the construction phase and bear significant weight. In addition to their substantial weight, insufficient waterproofing may result in water accumulation beneath the bricks, potentially leading to deterioration of the underlying waterproofing layer. Insulating coatings are the most economical and convenient option, with the key factor affecting their performance being the choice of filler material.

▲ Schematic diagram illustrating the function of thermal insulation coatings (as above)

Three common filler choices for insulating coatings are: perlite (hollow ceramic spheres), aerogel, and the emerging hollow glass microspheres.

Perlite, a byproduct of coal-fired power plants, has the highest thermal conductivity coefficient of the three, along with several drawbacks such as uneven particle size distribution, low strength, high impurity content, and adverse effects on final product color. Despite its flaws, perlite's low cost initially garnered favor among users when thermal insulation coatings first gained traction.

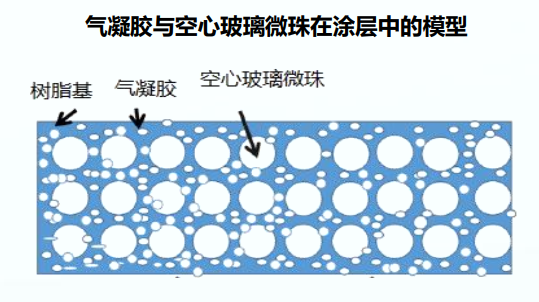

Aerogel, boasting extremely low density and thermal conductivity, caused quite a stir upon its market debut. However, in order to be used in coatings, aerogel must be combined with resin, a process prone to issues such as pore clogging, dispersion problems, increased thermal conductivity, powdering, and poor physical properties. Additionally, its high price limits widespread use.

Hollow glass microspheres, on the other hand, address the shortcomings of both perlite and aerogel. In recent years, they have gained popularity in thermal insulation applications. Here are some advantages of hollow glass microspheres:

1. Excellent thermal insulation: The tightly packed hollow glass microspheres contain sparse gas, resulting in a low thermal conductivity coefficient and outstanding thermal insulation properties.

2. Efficient filling: The spherical particle structure leads to a smaller surface area-to-volume ratio and lower oil absorption rate, significantly reducing the amount of resin and other components in coatings.

3. Superior environmental performance: Even with high filling amounts, the viscosity of the coating is only slightly increased, reducing solvent usage and thus toxic gas emissions during application, effectively lowering VOC emissions.

4. The spherical shape of hollow glass microspheres acts as bearings, minimizing friction and enhancing the flow and spreadability of coatings, facilitating construction.

5. Coatings exhibit better waterproofing, anti-fouling, and corrosion resistance properties.

|

Perlite (Hollow Ceramic Spheres) |

Aerogel | Hollow Glass Microspheres | |

|---|---|---|---|

| Strength | Poor, fragile | Poor, fragile | High |

| Compatibility with resin | Good | Poor | Good |

| Thermal conductivity coefficient | High | Low, but with pore-clogging risk | Low |

| Price | Low | Extremely high | Medium, but low density with high filling capacity |

Additionally, hollow glass microspheres can be used in conjunction with aerogel to synergistically improve coating performance and reduce raw material costs. The synergistic effects of hollow glass microspheres and aerogel in thermal insulation coatings are illustrated in the diagram below.

Laboratory data:

| Formulation | Thermal Conductivity (W/(m·K)) | Density (g/cm³) | Hollow Glass Microsphere Content | |

|---|---|---|---|---|

| 1 | Thermal insulation coating | 0.2 | 1.5 | 0 |

| 2 | Thermal insulation coating + hollow glass microspheres | 0.065 | 0.5 | 25% |

| 3 | Thermal insulation coating + hollow glass microspheres + aerogel | 0.035 | 0.3 | Formula 2 + 1% aerogel |

CONTACT US

Kelly Chemical Corporation

Electronics

TEL:(02)2762-1985 ext 11200

Online Message

Leave your contact information,

and we will get in touch with you soon.

Email Consultation

After receiving your email,

we will process it as soon as possible.send Email