Example of Chemical Mechanical Grinding & Cutting Wastewater Treatment - High Efficiency Measurement Report of New Generation Energy Powder Flocculant PART III

Chemical Mechanical Polishing (CMP) / Back Grinding (BG) Wastewater Treatment - Single-Agent Powder Coagulant/Aggregant Practical Cases

~ New Choice for Semiconductor Wafer Polishing/Cutting Wastewater Treatment ~

The semiconductor manufacturing industry is one of the most crucial industries in many advanced countries. The Chemical Mechanical Polishing process (CMP) and wafer cutting into grains process (BG) are necessary steps due to the differences in wafer surface materials, requiring the leveling of protective layers. Both processes involve the use of large volumes of Ultrapure Water for cleaning and cooling, resulting in the carrying out of silicon powder in CMP and BG wastewater. Under high turbidity conditions with a large amount of suspended silicon powder (ranging from 500 to 20,000 NTU), CMP wastewater appears dark brown, while BG wastewater appears dark gray. To avoid environmental pollution caused by improper treatment of silicon powder in large amounts of wastewater, Gonlong Chemical recommends the application of "single-agent powder coagulant/aggregant" for CMP and BG wastewater treatment in semiconductor packaging and testing plants. Its product characteristics include:

- Reducing the concentration of suspended solids (SS) in effluent water.

- Functions of flocculation, coagulation, aiding dehydration, and oil adsorption.

- Produces drier, better draining sludge that is less prone to membrane fouling; the sludge structure is more solid and less likely to penetrate through filter cloth pores under pressure.

- For some semiconductor packaging and testing plants' CMP and BG wastewater, adding a single-agent powder coagulant/aggregant can effectively reduce the usage of coagulant (PAC), flocculant (PAM), and liquid alkali (NaOH).

- Compared to the original wastewater treatment process (e.g., PAC, PAM), the amount of sludge generated can be significantly reduced.

- Contains no harmful environmental components and is not harmful to humans.

Case One: CMP Wastewater

Evaluation Period: 2018/3~2018/9

Client: OO Corporation

Issues Addressed:

1. Suspended solids concentration close to 30 ppm (upper limit)

2. Presence of sludge floating on the surface of the sedimentation tank

3. Foaming issues in the mixing tank due to surfactants

Treatment Scale: Approximately 225 CMD

Treatment Process: Single-agent powder coagulant/aggregant (Neosorb EMU-B6, https://reurl.cc/kaylq)]

Treatment Results:

- The use of a single-agent powder coagulant/aggregant improved the gel structure (compact aggregation) of CMP wastewater, achieving rapid settling effects.

- Reduction in the usage of chemicals in the original wastewater treatment process, facilitating material management.

- Not affected by pH, convenient operation, and clear water quality after treatment.

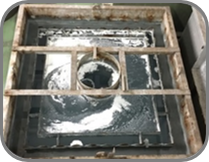

Case Two: BG Wastewater

Evaluation Period: 2017/10~2018/2

Client: OO Technology Co., Ltd.

Issues Addressed: White foam and suspended solids above the sedimentation tank.

Treatment Scale: Approximately 45 CMD

Treatment Process: Single-agent powder coagulant/aggregant (Neosorb GS-AN, https://reurl.cc/kaylq)

Treatment Results:

- The upper layer of the chemical settling tank is colorless with no suspended solids.

- Low increases in turbidity and EC (electrical conductivity) in each tank.

- No need for the original wastewater treatment process chemicals (PAC, PAM), and simultaneously reduced usage of NaOH and H2SO4.

- No need to adjust pH, convenient operation.

.png)

CONTACT US

Kelly Chemical Corporation

Electronics

TEL:(02)2762-1985 ext 11200

Online Message

Leave your contact information,

and we will get in touch with you soon.

Email Consultation

After receiving your email,

we will process it as soon as possible.send Email