Introduction to Thermal Interface Materials: Thermal Paste and Liquid Metal

Introduction to Thermal Interface Materials (TIM)

Thermal Interface Materials (TIM) are essential for improving heat transfer efficiency between heat-generating components and cooling devices. Their primary function is to fill the microscopic gaps between surfaces, reducing thermal resistance and ensuring effective heat transfer to the heat sink, which helps stabilize component performance and extend its lifespan.

Core Functions

Reducing Thermal Resistance: TIMs fill small air gaps between uneven surfaces, minimizing the barriers to heat transfer.

Improving Thermal Efficiency: TIMs help the cooling system remove heat from components more quickly.

Common Types

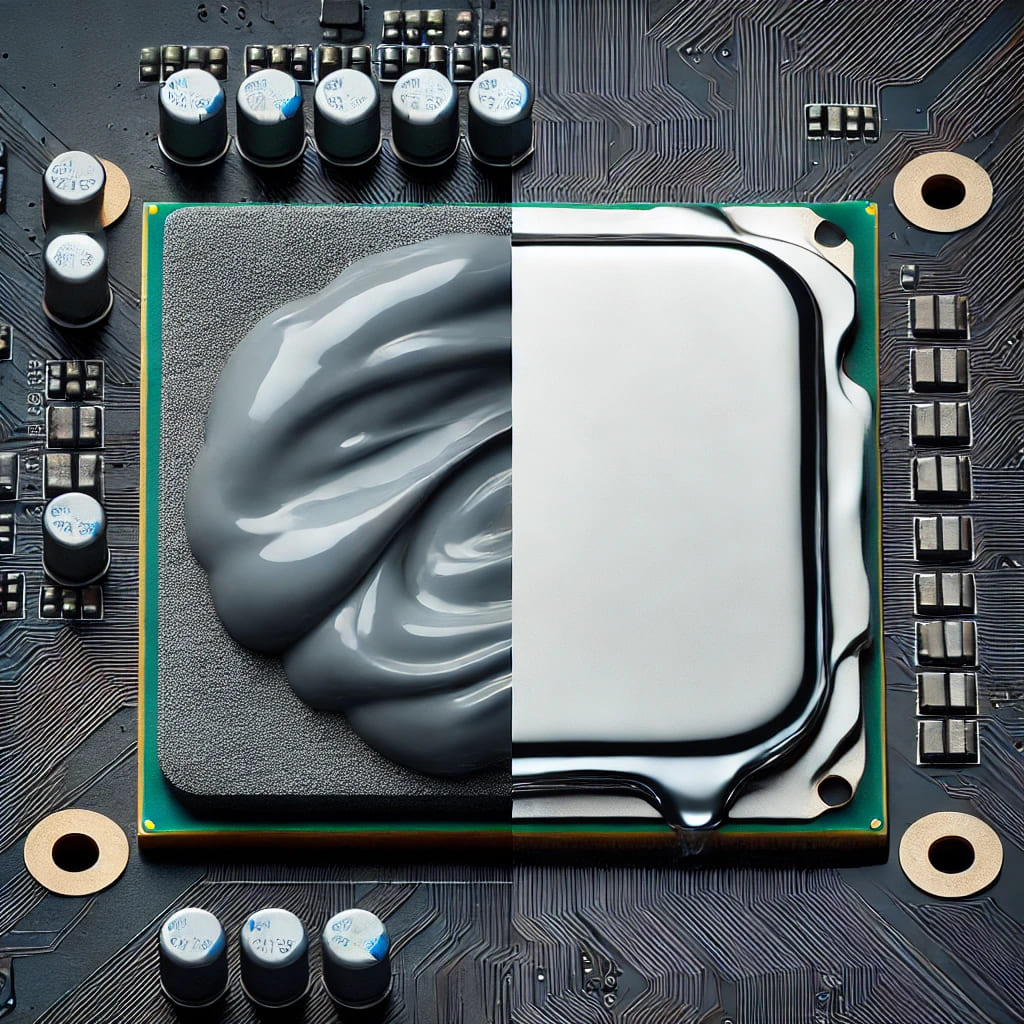

Thermal Paste: A gel-like substance, ideal for high-precision applications.

Thermal Pads: Sheet materials, easy to install and versatile for different applications.

Phase Change Materials: Melt when heated, filling gaps and improving thermal conductivity.

Thermal Adhesives: Combine bonding and thermal conductivity functions.

Liquid Metal: Offers exceptional thermal conductivity and flowability, quickly transferring heat from the component to the cooling system or environment.

Trends in TIMs

As electronics become more powerful and compact, the demand for TIMs continues to diversify. The future will likely see a shift toward TIMs with high thermal conductivity, low costs, and environmentally friendly properties.

Thermal Paste

In the development of modern electronic devices becoming thinner and lighter, thermal paste quietly plays a critical role in solving heat dissipation problems. Although often overlooked, it is an indispensable core material for thermal conduction.

What is Thermal Paste?

Thermal paste is a gel-like substance with high thermal conductivity, primarily used between electronic components (like CPUs and GPUs) and heat sinks. Its function is to fill the tiny gaps between these surfaces, eliminating the thermal resistance caused by air and enabling efficient heat transfer to the heat sink, ultimately improving cooling efficiency.

Types and Characteristics

Thermal paste is categorized based on its thermal conductivity, viscosity, electrical resistance, and working temperature:

High Thermal Conductivity: Suitable for high-performance devices.

Easy to Process: Designed for stability in various environments. Different products cater to different needs, such as the PT series for extreme thermal conductivity and the AT series for ease of application.

Main Applications

Thermal paste is widely used in:

Electronic Devices: Computers, smartphones, tablets, etc.

Lighting Systems: LED lights.

Power Supplies: To maintain stable operation.

Memory Modules: To enhance thermal performance.

Purchasing Guide

When selecting thermal paste, consider:

Thermal Conductivity: The higher, the better the heat dissipation.

Viscosity: Should be easy to apply but not too runny.

Electrical Resistance: To prevent short circuits.

Working Temperature: Ensure stability in the desired temperature range.

Price: Choose based on performance and budget.

Conclusion

Thermal paste plays a crucial role in heat dissipation for electronic components. The right choice of thermal paste can enhance device performance, extend its lifespan, and provide reliable operation.

Liquid Metal

Liquid metal is used for high-efficiency heat dissipation in electronic components such as CPUs and GPUs. Its high thermal conductivity (far surpassing thermal paste) enables rapid heat transfer and fills microscopic gaps between the component and heat sink, significantly reducing thermal resistance, making it ideal for high-performance systems.

How to Choose Liquid Metal for Cooling

Thermal Conductivity: Choose products with high thermal conductivity (usually above 40-80 W/mK).

Safety: Avoid liquid metals that may corrode aluminum heat sinks, and use suitable surface treatments.

Application Context: Liquid metal is the best choice for extreme cooling needs (e.g., overclocked systems).

Ease of Application: Ensure the material is easy to apply and avoid direct contact with the circuit board to prevent short circuits.

If you have any questions regarding our products, feel free to reach out via email or phone.

#ThermalInterfaceMaterials #TIMs #AI #ThermalPaste #LiquidMetal #Servers

For detailed technical or product information (TDS/SDS), please visit our "Contact Us" page for more information: https://www.es-kelly.com/news.php

CONTACT US

Kelly Chemical Corporation

Electronics

TEL:(02)2762-1985 ext 11200

Online Message

Leave your contact information,

and we will get in touch with you soon.

Email Consultation

After receiving your email,

we will process it as soon as possible.send Email