Best Practices for Coagulation and Flocculation in Wastewater Treatment

Choosing the Right Coagulants and Flocculants: Key to Successful Wastewater Treatment

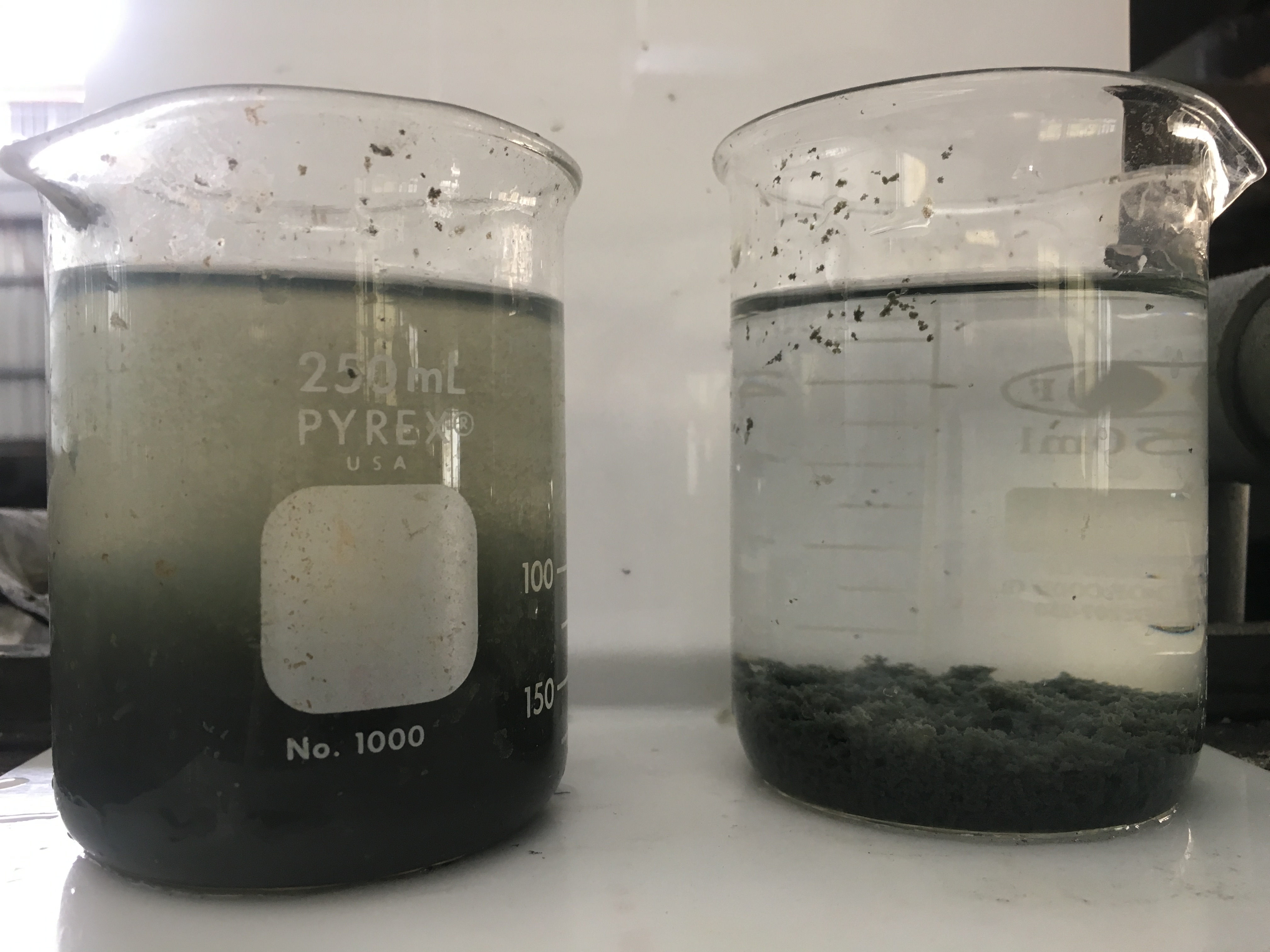

Currently, the selection of coagulants and flocculants has become a crucial factor in determining the effectiveness of wastewater treatment. In wastewater treatment systems, the processes of coagulation and flocculation/agglomeration are nearly irreplaceable. They are not only technologically mature, simple in design, and easy to operate, but also relatively inexpensive. However, because these technical features are easy to handle, their essence and design principles are often overlooked, leading to poor treatment results and issues such as abnormal effluent quality, sludge floating, water turbidity, and excessive sludge. Therefore, successful wastewater treatment must begin with these two units, coagulation and flocculation/agglomeration, to ensure stable effluent quality and provide a good foundation for subsequent treatment.

Functions and Types of Coagulants

In the wastewater treatment process, the primary role of coagulants is to neutralize the negatively charged suspended particles in the water, thereby reducing the repulsive forces between the particles. This promotes particle aggregation and growth, ultimately forming larger and more easily settled particles.

Coagulants are mainly divided into two categories: inorganic and organic. Among them, inorganic coagulants can be further divided into monomers and polymers. Common examples include aluminum sulfate (alum), aluminum chloride, ferric sulfate, ferric chloride, polyaluminum chloride, and polyferric sulfate. Although inorganic coagulants are relatively inexpensive, it is important to pay attention to their quality and composition when selecting them, as these coagulants are often by-products from other industries and may contain components that interfere with wastewater treatment.

Organic Coagulants

| Classification | Product name | Advantages | Disadvantages |

|---|---|---|---|

| Traditional Coagulants | Ferric Chloride | Typical effective coagulants | Used between pH 5.5-8.5, typically requiring liquid alkali addition for optimal pH. Generally requires larger dosage and longer reaction time. |

| Ferric Sulfate | |||

| Aluminum Sulfate | |||

| Polymeric Coagulants | Polymeric Ferric Chloride | Low sensitivity to pH (effective 4.5-9.5). Shorter mixing time. Sludge is more resilient and less in quantity. | Higher cost compared to traditional coagulants. |

| Polymeric Aluminum Sulfate | |||

| Polymeric Aluminum Chloride | |||

| Polymeric Aluminum Ferric Sulfate | |||

| Polymeric Aluminum Ferric Chloride |

Organic coagulants are characterized by their high concentration of positive charges, allowing them to achieve charge neutralization with relatively small amounts. They are suitable for treating high-content wastewater, such as that containing dyes and paints. Under appropriate operating conditions, these coagulants can effectively achieve decolorization, water clarification, and reduced sludge production. Currently, there are also blended coagulants available on the market, which combine the advantages of inorganic and organic coagulants to simplify operation and enhance coagulation effectiveness.

Functions and Types of Flocculants Agents

Even after coagulants have initiated particle aggregation, flocculants/aggregating agents are still needed to enlarge the particles and accelerate their settling. Flocculants/aggregating agents can be classified into four categories based on their charge: cationic, anionic, amphoteric, and non-ionic. Anionic flocculants/aggregating agents are the most commonly used because they help neutralize the charge after using positively charged coagulants. However, in certain situations, cationic or non-ionic flocculants/aggregating agents might be more effective. Therefore, when selecting flocculants/aggregating agents, it is essential to consider their charge characteristics, as well as evaluate their viscosity, molecular weight, and results from jar tests.

Common classifications of flocculants agents include:

| Classification | Product name | Advantages | Disadvantages |

|---|---|---|---|

| Organic Cationic polymer | PolyDiallydimethyl Am monium Chloride, PolyDADMAC | Produces more compact, shear-resistant sludge. Generally used in conjunction with inorganic coagulants. | Increases the complexity of the coagulation/flocculation, but correct use can enhance process performance and reduce costs. |

| Epichlorohydrin Dimethylamine Polymer, Epi-DMA | |||

| Trimethylammonium Chloride | |||

| Quaternary Ammonium Salt | |||

| Polydimethyl Aminomethyl Polyacrylamide | |||

| Nonionic organic polymer | Polyacrylamides | ||

| Polyethylene Oxide | |||

| Anionic organic polymer | Polyacrylamides | Forms larger sludge flocs through bridging action. | |

| Polyacrylic Acid | |||

| Polyacrylates |

In addition, there are now single-dose powdered flocculants that combine the functions of coagulation and flocculation/agglomeration in one dose, greatly simplifying the operation process. These powdered flocculants are suitable for treating wastewater containing fats and surfactants, with advantages in accelerating reactions and improving sludge dewatering. However, selecting the appropriate powdered flocculant still requires jar testing to ensure optimal results.

There are a wide variety of powdered flocculants available on the market, each with unique characteristics suitable for treating different types of wastewater.

Common One-Step powdered flocculants:

- General - These flocculants are suitable for treating wastewater with trace amounts of fats and surfactants. They effectively address small particles and suspended solids in general industrial wastewater.

- Demulsifying - Specifically designed for wastewater containing moderate levels of fats or surfactants, these flocculants rapidly break emulsions and promote the separation of fats and water, improving treatment efficiency.

- Rapid - Emphasizing reaction speed, these flocculants are ideal for environments requiring quick treatment. They promote fast particle settling and reduce processing time.

- Recovery - Designed for low-conductivity wastewater, these flocculants do not clog membranes, making them suitable for systems requiring efficient membrane filtration. They extend membrane life and enhance system efficiency.

Conclusion

In summary, the selection of coagulants and flocculants/aggregating agents is crucial to the success of wastewater treatment. Proper selection of chemicals and operating conditions should rely on professional evaluation and testing to achieve optimal results, ensuring effective particle aggregation and rapid settling, thus achieving ideal treatment outcomes.

CONTACT US

Kelly Chemical Corporation

Electronics

TEL:(02)2762-1985 ext 11200

Online Message

Leave your contact information,

and we will get in touch with you soon.

Email Consultation

After receiving your email,

we will process it as soon as possible.send Email