Paint removal example ~ Actual measurement of two PVD vacuum coating stripping methods!! Replace sandblasting!!

PVD Coating Removal Method ~ Compliant with EU REACH Regulations~

Replacing Sandblasting! Chemical coating removal is faster and more effective for large quantities of workpieces!

PVD refers to the process of depositing the desired coating material onto a workpiece in a vacuum environment, either in gas or plasma form. Due to its versatility and excellent wear and chemical resistance, PVD coatings find applications in various fields including optics, electronics, and semiconductor industries. However, some workpieces may require coating removal for reusability or refurbishment, thus necessitating a coating removal process.

Comparison of Three Treatment Methods

| Treatment Method | Replace with New Parts | Sandblasting | Chemical Coating Removal |

|---|---|---|---|

| Impact on the Part | Entirely New Parts | Potential deformation, wear, damage to parts | No particular impact |

| Impact on Production Environment | No Impact | Residual powder may contaminate vacuum coating equipment, clean rooms | Process involves water rinsing and drying, no environmental contamination potential |

| Cost | High | Low | Medium |

| Labor | Low | High | Medium |

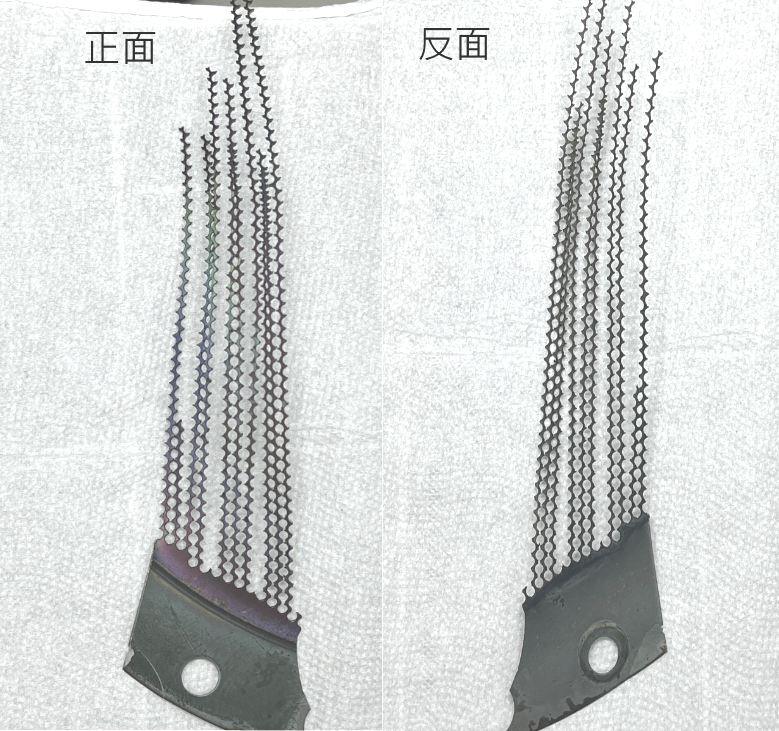

Optical Molybdenum Electrode Plate Coating Removal

Workpiece: Molybdenum electrode plate

Purpose: Accumulated coatings on the surface due to multiple coating procedures, aiming for reusability to reduce costs.

Conditions: Controx E 230 100% original solution, heated to 90°C, reaction time of 15 minutes.

Results: After coating removal, a simple rinse with deionized water reveals the original metallic color of the molybdenum plate.

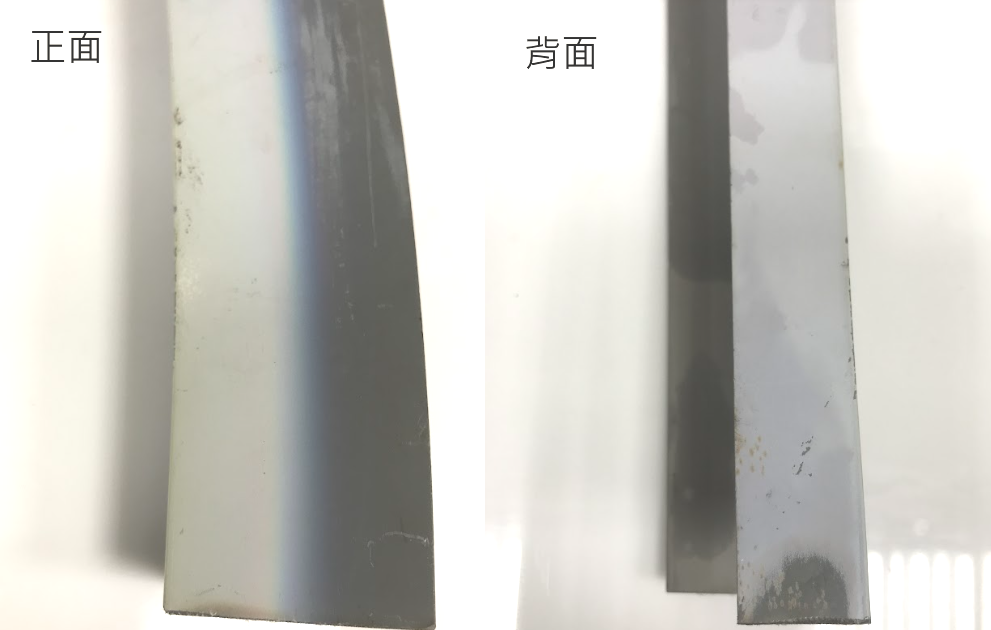

Before Coating Removal:

After Coating Removal:

.png)

Stainless Steel Component PVD Coating Removal

Workpiece: Stainless steel component

Purpose: Processing heavy-duty components, aiming for complete coating removal for re-coating.

Conditions: Controx E 230 100% original solution, heated to 70°C, reaction time of 30 minutes.

Results: After coating removal, a simple rinse with deionized water reveals the original metallic color of the stainless steel, enabling further processing.

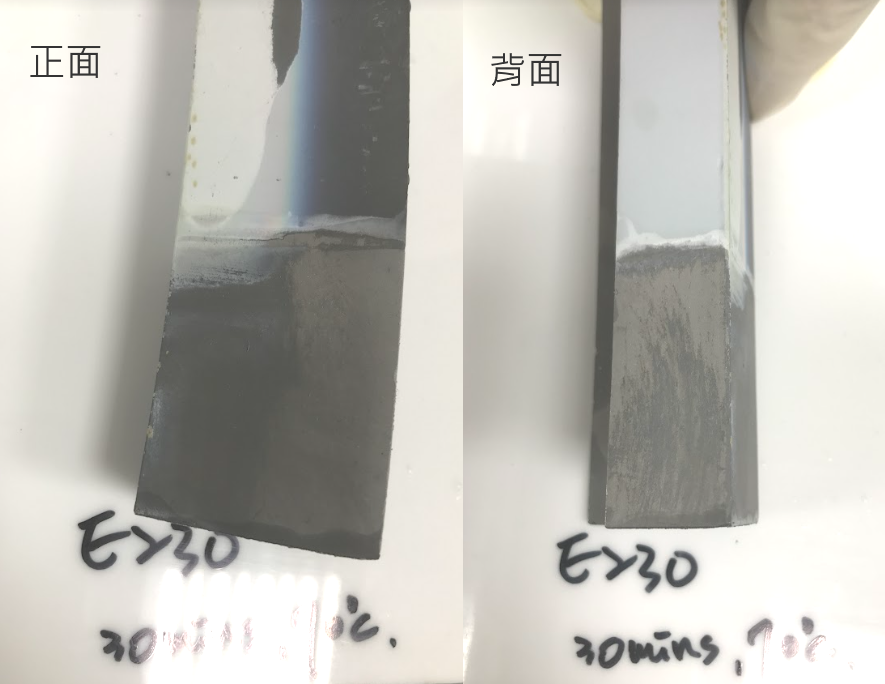

Before Coating Removal:

After Coating Removal:

CONTACT US

Kelly Chemical Corporation

Electronics

TEL:(02)2762-1985 ext 11200

Online Message

Leave your contact information,

and we will get in touch with you soon.

Email Consultation

After receiving your email,

we will process it as soon as possible.send Email