Paint removal solution ~ complies with EU requirements and can be recycled and reused! Are you still using methylene chloride to remove paint?

Are you still using dichloromethane for paint stripping? The toxicity and volatility of dichloromethane are often worrisome~

Heavy-duty paint stripping can also be done using more environmentally friendly methods, compliant with EU regulations. It might be worth a try!!

Dichloromethane (DCM) is an organic solvent with a low boiling point, non-flammable, and strong solvency widely used for various purposes, including paint strippers, diluents, and detergents. Due to its low boiling point and high volatility, using it without proper safety precautions can lead to significant risks of exposure, including neurological paralysis and respiratory failure.

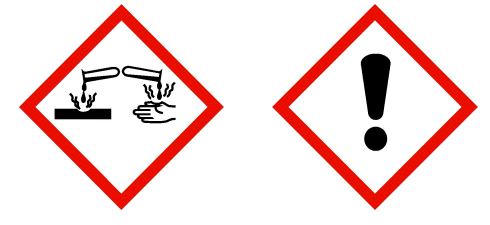

▲ The hazards of dichloromethane are significant, with high risks associated with its indoor use.

Due to increasing concerns about health and the environment in recent years, the high-risk nature of using traditional chlorinated solvents for paint stripping has gradually raised safety concerns. The use of such hazardous paint strippers is being phased out and banned in some regions. In 2009, the EU passed Decision No 455/2009/EC, regulating the sale and use of dichloromethane. Restrictions on dichloromethane are becoming increasingly stringent internationally. Therefore, there is a need to find better alternatives for organic solvent paint stripping, and environmentally friendly alkaline and acidic paint stripping is the future development direction. Moreover, it is a technically and economically feasible way to remove paint auxiliaries (racks, grates, painting equipment), and mispainted parts.

Comparison between dichloromethane paint stripping and eco-friendly paint stripping solutions:

|

Dichloromethane (DCM) Paint Stripping |

Eco-friendly Paint Stripping |

|

|

Regulations |

Usage restricted or banned in some areas. |

Compliant with REACH regulations, free from NMP, NEP, and other SVHC.。 |

|

Applicable Materials |

Applicable to almost all types of coatings, wooden substrates do not swell. |

Applicable to all common coatings on various substrates, also suitable for sensitive surfaces. |

| Stripping Time | Relatively fast, about 10-20 minutes. | Longer time, about 10-60 minutes. |

| Operating Method | Immersion, used at room temperature. | Immersion, spraying, used at room temperature or heated. |

| Operating Cost | Lower raw material cost, about 40-60 TWD/kg. | Higher cost for eco-friendly paint stripping, about 100-200 TWD/kg. |

| Solution Bath Usage Time | Solvent stripping, the solution is prone to aging, requiring more frequent solution changes. |

Solution stripping with dissolution, infiltration, and expansion, allowing longer usage time. |

|

Hazardous Goods Transport Category |

Class 6 dangerous goods: substances that, in case of ingestion, inhalation, or skin contact, cause poisoning or contain microorganisms that cause disease. | Class 8 dangerous goods: substances that, upon contact with humans or objects, cause significant damage in a short time. |

| Hazard Warning |  |

|

Under EU restrictions, for removing paint from steel parts, an economical water-based alkaline stripping concentrate can be used, diluted with water before use. For removing paint from aluminum, zinc, and other non-ferrous metals, an organic heat stripping agent can be used. Effective paint stripping can be carried out at working temperatures between 20°C and 120°C, depending on the type of paint to be removed and the specified process conditions. Used paint stripping solutions can be filtered to remove paint residues and impurities, and can be recycled and reused for the next paint stripping, which is both economical and environmentally friendly. Here are several types of eco-friendly paint stripping solutions:

| Type | Features | Applicable Coatings | Operating Method |

| Mixed-alkaline Solvent | For use on steel, magnesium, corrosion-resistant plastics, not suitable for aluminum or zinc substrates. | Can remove synthetic resin coatings, electroplating coatings, polyester powder coatings, oil carbon, etc. | Used for immersion or spraying equipment. Heat to 70-80°C for best results.If there are more difficult-to-remove coatings, the temperature can be heated to 110°C. Before use, dilute the original liquid with water in a 1:1 ratio. |

| Mixed-acid Solvent | High-boiling-point organic type room-temperature paint stripper, can remove paint on iron and steel materials that have been cured. |

At room temperature, it can remove paint and powder coatings that have been cured on iron and steel metals.。 |

Used by immersion. Needs to be installed in a special steel material with a completely closed seal. The stripped paint will precipitate, so it is recommended to use a screen regularly to filter out impurities. |

| Mixed Solvent Type | Eco-friendly organic heat stripping solution for steel, steel, aluminum, and other light metals. | It can also be used for ambient temperature paint stripping depending on the type of paint. | Dissolves cured paints and powder coatings, such as polyester fibers and polyurethane varnishes. Used for immersion and spraying. About 60-80°C (depending on the type of coating, it may also be 20-50°C). Use directly. |

▲Comparing dichloromethane paint stripping with environmentally friendly paint stripping solutions

Environmentally friendly paint stripping can be customized with tailored additives or accelerators to ensure consistent paint removal effects and longer service life for the corresponding products. Depending on operating conditions, paint layer types, and substrate materials, environmentally friendly paint stripping can consider methods such as heating or stripping at room temperature. Additionally, paste and liquid cold strippers can be used for stripping tasks where heating equipment is unavailable.

Hot Paint Stripping

- Organic heat paint strippers for use on all coatings on aluminum and black metal surfaces.

- Steel surfaces can use water-based alkaline heat paint strippers.

Cold Paint Stripping

- Liquid and paste paint strippers suitable for all coatings on aluminum and black metal surfaces.

As restrictions on dichloromethane become increasingly stringent worldwide due to its effects on human health, the future of paint stripping should focus on less toxic and less hazardous alternatives. Early assessment and introduction of environmentally friendly paint stripping methods are effective and practical measures to improve working conditions and reduce factory risks.

CONTACT US

Kelly Chemical Corporation

Electronics

TEL:(02)2762-1985 ext 11200

Online Message

Leave your contact information,

and we will get in touch with you soon.

Email Consultation

After receiving your email,

we will process it as soon as possible.send Email