Wastewater treatment example: SS suspended particulate improvement example! Reappearance of clarified discharge water! Features of one-dose powder flocculant PART 1

Is there an excessive amount of fine suspended solids in the wastewater? Try adding powdered coagulants if excessive amounts of coagulants or polymers have failed to show significant improvement.

Metal Processing Plant in Taichung

Wastewater Volume: 500 tons per day

SS Concentration: 200-300 mg/L

Case Explanation:

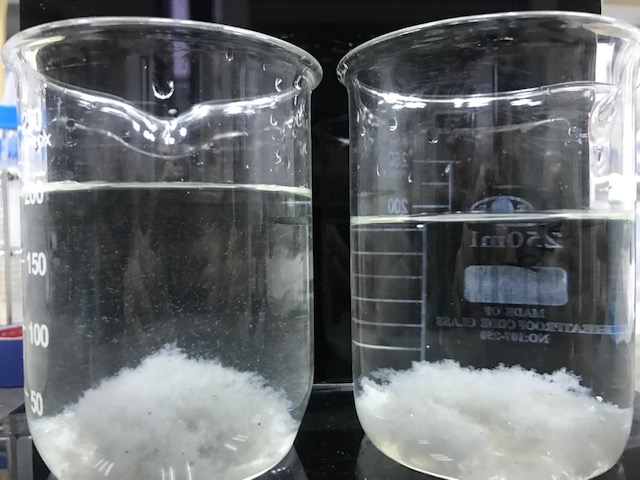

The wastewater from a metal processing plant in Taichung consists mainly of process cleaning wastewater and a small amount of saponification wastewater. Only polyaluminum chloride (PAC) and polymeric coagulants (PAM) are used as the main treatment chemicals in the wastewater treatment plant. Since direct discharge is allowed, the effluent requirement for suspended solids (SS) is 30 mg/L or less. After an in-depth understanding by personnel from Kung Lung Chemical, it was found that the presence of detergents and saponifying agents in the wastewater made effective coagulation difficult. Although sludge could settle, there were small gelatinous flocs still suspended in the supernatant, posing a concern for SS exceeding the discharge standard. Powdered coagulants proved to be highly effective in addressing this issue, causing individual sludge particles to increase in size while increasing the unit weight of sludge to enhance settling velocity. The SS concentration was consistently below the discharge standard, which was originally between 50-100 mg/L.

▲ Powdered coagulants enable faster settling by aggregating sludge particles (as shown in the cup on the right).

CONTACT US

Kelly Chemical Corporation

Electronics

TEL:(02)2762-1985 ext 11200

Online Message

Leave your contact information,

and we will get in touch with you soon.

Email Consultation

After receiving your email,

we will process it as soon as possible.send Email