TPCA 2025: How Low-Carbon Materials Are Redrawing the PCB Supply Chain Landscape

Low carbon is no longer a bonus — it's the entry ticket to the supply chain

Every October, the TPCA Show is seen as Asia's annual barometer for the PCB and electronic materials industry. The moment you step into the exhibition hall this year, one thing stands out: the buzzwords on the banners are no longer "equipment, capacity, yield," but "AI, low dielectric, thermal management, low carbon, and heterogeneous integration."

These are not marketing slogans, but real, on-site demands. The industry is shifting from "faster and cheaper" to "faster, more stable, and more energy-efficient," competing not just on cost, but on carbon risk and system performance.

1. From manufacturing efficiency to system performance: rediscovering the value of PCB and packaging

In the past, PCB discussions mostly revolved around three things:

- Cost

- Production volume

- Yield rate

With the rise of generative AI and high-performance computing, everything has changed. PCB and IC packaging are no longer just "boards that hold components," but key materials influencing signal transmission, heat dissipation, and overall system performance.

The four most noticeable directions of change are:

| New Applications | New Requirements |

|---|---|

| AI servers | Exploding power demand → requires improved thermal and reliability performance |

| High-speed computing / Cloud | Low dielectric, low loss materials become the standard |

| Edge computing | Thinner, more heat-resistant, and highly integrated packaging |

| ESG / Sustainability | Quantifiable, auditable data on materials, energy, and wastewater |

In short: performance is no longer determined by the chip alone — materials and packaging now take center stage. PCB has moved from supporting role to protagonist.

2. Heat is not the problem — it's the battlefield: thermal management and reliability as core competitiveness

As AI server power surges, the entire show floor is asking:

- How to accelerate heat transfer

- How to prevent package warpage

- How to balance thermal performance and processability

Key R&D directions include:

- Enhanced thermal fillers (BN, AlN, metal powders, etc.)

- New-generation TIM (Thermal Interface Materials)

- Lowering CTE (Coefficient of Thermal Expansion)

- Adoption of metal or composite substrates

3. The low-dielectric era begins: Dk / Df become PCB material KPIs

The growing need for high-speed transmission has ushered PCB materials into a new era of low dielectric constant and low loss.

New material solutions on display include:

- Modified epoxy systems (reduced polarity, maintained processability)

- PPE / PPO resin systems

- Optimized resin × glass fiber × structural composites

Board materials are no longer compared only by Tg, heat resistance, or cost — but directly by:

- Dk (dielectric constant)

- Df (dissipation factor)

Low dielectric performance has officially become a key KPI.

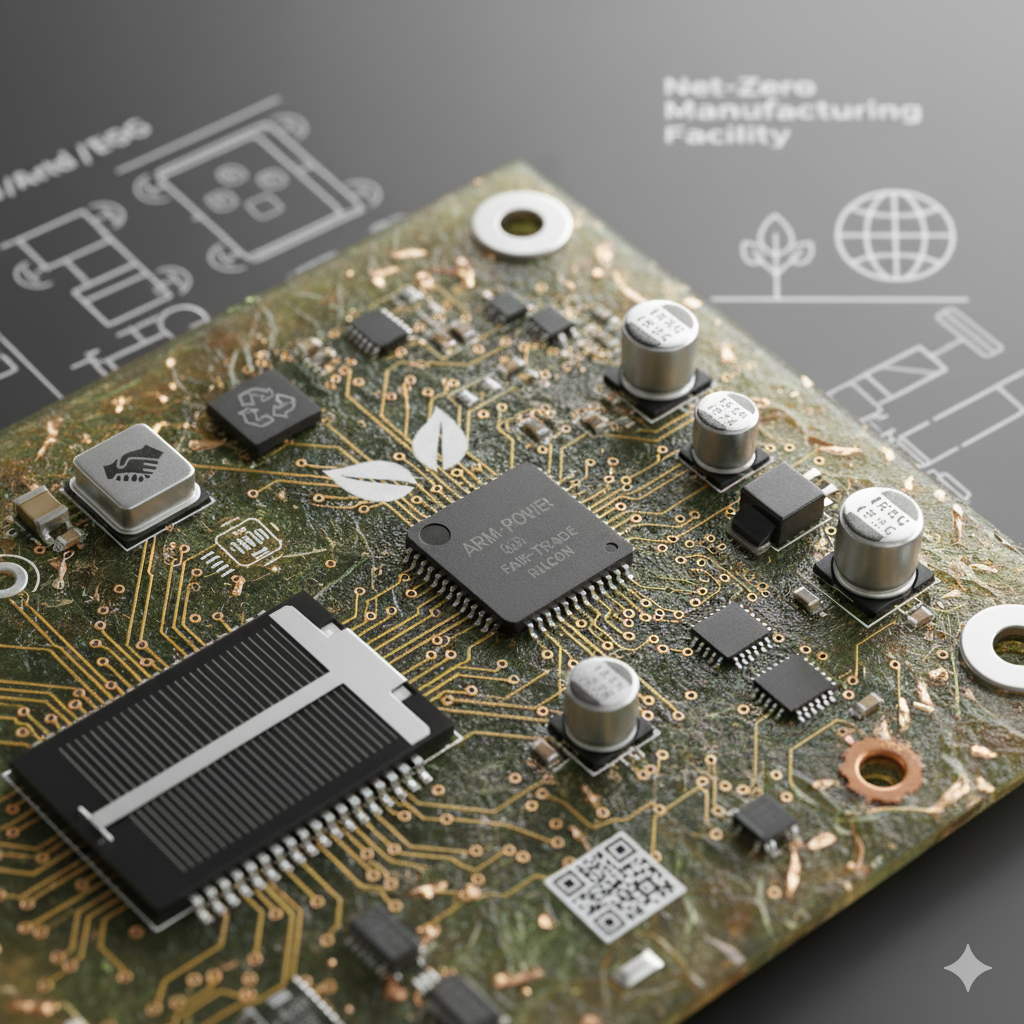

4. ESG moves from slogans to mandatory fields on procurement forms

One of the biggest shifts at TPCA this year is that sustainability is no longer a branding statement — it's a purchasing requirement.

Customers are not asking whether you "support low carbon," but whether you can prove it.

Procurement now requires verifiable data such as:

- Product Carbon Footprint (PCF)

- Life Cycle Assessment (LCA)

- Metal and chemical reduction

- Wastewater and heavy metal emission control

In other words: no carbon data, no purchase order. Low carbon has become the entry ticket to the supply chain.

5. Low carbon beyond slogans: materials and processes as twin engines

Achieving real carbon reduction means more than changing the message — it requires simultaneous action on both materials and process fronts.

Three key directions for materials:

- Substitution: bio-based epoxy, PI alternatives, solvent replacements

- Reduction: thinner metal layers or improved thermal efficiency without performance loss

- Breakthrough: silver paste → low-temp sintered copper, next-gen low-Dk resins

Four focuses on the process side:

| Item | Objective |

|---|---|

| Thermal process optimization (lower temp / shorter time) | Reduce energy consumption |

| Viscosity-speed matching | Reduce rework and material waste |

| Chemical regeneration & metal recovery | Lower carbon and hazardous waste output |

| Online monitoring of pH / concentration | Ensure process stability and reduce scrap |

The key is not just to "go green," but to achieve: low carbon + uncompromised reliability + acceptable cost = feasible adoption.

Conclusion: Low carbon is the new standard, not an option; performance is the baseline, not the goal.

Connecting all the signals from TPCA 2025 leads to one clear conclusion: the electronics industry's race is evolving from chip competition to a combined race of “materials × sustainability.”

Future winners will be those who can deliver:

- High performance

- Low carbon emissions

- Verifiable data

- Scalable production

Materials define how fast technology can move forward, but low carbon determines how far it can go.

#TPCA2025 #LowDielectric #LowLoss #LowCarbon #ESG

CONTACT US

Kelly Chemical Corporation

Electronics

TEL:(02)2762-1985 ext 11200

Online Message

Leave your contact information,

and we will get in touch with you soon.

Email Consultation

After receiving your email,

we will process it as soon as possible.send Email