Heavy Metal Precipitating Agents: Small Additives, Big Impact

Heavy Metal Precipitating Agents: Small Additives, Big Impact

Did you know? Wastewater isn't always "garbage"—sometimes it can be reborn!

In the factory, there's a chemical agent that you often overlooked—the heavy metal precipitant agent which is quietly doing incredible work. A heavy metal precipitant agent can catch the heavy metal in the water at once, turn contaminated black water into clear water, and even promote the resource recovery. It may sound like magic, but this is real technology. Today, let's get to know this small hero that's transforming both industry and the environment.

1. Challenges in dealing with industrial water

In industries such as electroplating, PCB manufacturing, semiconductors, and surface treatment, water is an indispensable resource used every day. However, huge volumes of process water pose tough challenges, because its wastewater often contains heavy metal ions such as copper, nickel, lead, zinc, and cadmium. If wastewater is not properly treated, these heavy metal ions can enter rivers and groundwater, harm ecosystems, and may eventually back to our daily lives.

In the past, factories commonly used lime neutralization or sulfide precipitation. While these methods can remove some heavy metal ions, they are far less effective against chelated metals or ultra-low residual concentrations. In other words, traditional methods act like a coarse sieve: they can catch the big particles, but smaller harmful substances still slip through.

At this point, heavy metal precipitant agent have emerged as a new solution for the industry. Through precise chemical reactions, they can firmly “capture” the metals, turning them into insoluble precipitates and significantly improving removal efficiency.

2. Secret of Heavy Metal Precipitant Agents: Small Additives, Big Impact

Using KT-Z60w as an example, its main components include hydropolysulfide, sodium hydrosulfide, and alkaline additives, enabling it to react quickly with various transition metal ions. Its advantages go beyond high efficiency and include the following:

- High performance: Exhibits a strong affinity for Cu²⁺, Ni²⁺, Zn²⁺, Cd²⁺, and can even reduce concentrations to the ppb level.

- User-friendly: Supplied in liquid form, with dosage precisely adjustable according to water quality—ideal for automated dosing systems.

- Strong compatibility: Can be used alongside flocculants and coagulant aids to produce larger, better-settling precipitate particles.

- Safe handling: Must be kept away from acids to prevent H₂S release, but can be safely operated under good ventilation and proper protection.

These features make heavy metal precipitate agent not just a "water treatment chemical," but a reliable tool that supports industrial stability and environmental sustainability.

3. Case Study: Application of KT-Z60w in an Electroplating Plant

Take an electroplating plant as an example: it needed to treat 120 tons of zinc-containing wastewater every day. In the past, insufficient treatment efficiency often led to discharge standard violations, which not only increased operational pressure but also undermined customer confidence.

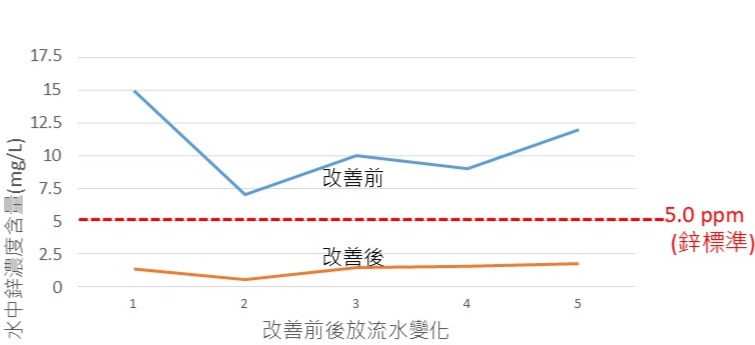

After introducing KT-Z60w, the operation process was designed as "dosing → mixing and stirring → settling," with a dosage ranging from 0.05–1.0 kg/m³. Test data showed that zinc concentrations dropped from greater than 10 ppm before treatment to less than 5 ppm afterward. This not only ensured stable compliance but also produced larger, easier-to-dewater sludge particles, significantly reducing downstream processing costs.

This case demonstrates that the value of heavy metal precipitate agent is more than just "meeting standards"—they also enhance plant efficiency, cost control, and customer trust.

4. Extended applications across industries

The value of heavy metal precipitate agent extends far beyond wastewater treatment. Thanks to their flexible chemical reactivity, they are now being explored in a growing number of fields:

- Soil Remediation

- Liquid chelating agents can be directly injected or sprayed onto contaminated soil, where they react with metals such as lead, cadmium, and mercury to reduce their toxicity.

- For long-term release, the liquid can be adsorbed onto a carrier to create granular forms, suitable for large-area soil improvement.

- Flue Gas Mercury Removal

- In coal-fired power plants or incinerators, chelating agents can serve as liquid absorbents, sprayed into scrubbers.

- They react with mercury in the gas phase, forming stable mercury sulfide precipitates and reducing mercury emissions into the atmosphere.

- Mining and Metallurgical Tailings Treatment

- In mine tailings ponds, adding liquid or slurry chelating agents enables rapid reaction with dissolved metals, lowering environmental risks.

- Recovery of Valuable Metals

- For wastewater containing silver, platinum, or palladium, chelating agents facilitate metal precipitation and recovery. This not only reduces pollution but also generates additional economic value.

These applications demonstrate that heavy metal precipitate agents are gradually expanding from "water treatment" to "cross-sector applications," representing new potential in environmental management and resource utilization.

5. Conclusion and Future Outlook

From turning black water into clear water and pollution into resources, heavy metal precipitate agents are making a transformative difference. They are not only tools for helping industries meet discharge standards but also key players in driving environmental sustainability.

Looking ahead, as the momentum of net-zero carbon emissions and the circular economy accelerates, heavy metal chelating agents will continue to evolve:

- Greener formulations: Reducing their own environmental footprint to align with sustainable chemistry trends.

- Smarter applications: Integrating sensors and automated controls for more precise and efficient dosing.

- Broader cross-sector use: Expanding from water treatment to soil remediation and resource recovery, opening up new fields of application.

CONTACT US

Kelly Chemical Corporation

Electronics

TEL:(02)2762-1985 ext 11200

Online Message

Leave your contact information,

and we will get in touch with you soon.

Email Consultation

After receiving your email,

we will process it as soon as possible.send Email