Application of Single-Component Powder Flocculant in Grinding Wastewater Treatment

The wastewater generated during the grinding process typically contains a high concentration of suspended solids (SS), metal particles, oils, and other organic pollutants. These contaminants not only degrade water quality but also pose challenges to subsequent discharge or recycling. This case study explores the successful application of the One-Step Powdery Flocculants in the treatment of grinding wastewater, effectively addressing pollution issues and improving treatment efficiency.

Challenges in Grinding Wastewater Treatment

Characteristics of Grinding Wastewater include:

- High Concentration of Suspended Solids (SS):

Metal particles and abrasive particles have difficulty in sedimentation, which negatively impacts water quality.

- Presence of Oils and Emulsified Substances:

These components reduce the effectiveness of conventional physical or chemical treatment methods.

- High Chemical Oxygen Demand (COD):

Some slurry contains organic additives, making the wastewater treatment more challenging.

- Heavy Sludge Treatment Load:

Traditional coagulants tend to generate large volumes of sludge, leading to high disposal and treatment costs.

Solution: One-Step Powder Flocculant

In this case, we use one-step powder flocculant. Our one-step powder flocculant can achieve multiple functions simultaneously, including flocculation, removal of suspended solids, oil separation, and sludge reduction, providing an efficient treatment solution for grinding wastewater.

Wastewater Treatment Process

- Mixing: Evenly add the one-step powder flocculant into the grinding wastewater.

- Flocculation and Solid-Liquid Separation: The high-efficiency flocculant quickly aggregates metal particles and oils to form larger flocs.

- Sedimentation: The enlarged and denser flocs accelerate the settling of suspended solids.

- Sludge Reduction: The specialized formulation helps minimize sludge generation, thereby reducing subsequent treatment costs.

Advantages of One-Step Powder Flocculant

✅ Efficient Removal of Metallic Suspended Solids:

Rapidly aggregates fine grinding particles to enhance solid-liquid separation efficiency.

✅ De-oiling and De-emulsification:

Effectively disrupts oil-water emulsions, making oil separation easier.

✅ Reduction in Sludge Generation:

Produces significantly less sludge compared to traditional coagulants, lowering treatment and disposal costs.

✅ Compliance with Environmental Regulations:

Ensures treated grinding wastewater meets discharge standards, minimizing environmental risks.

Case Study: Grinding wastewater from semiconductor packaging plants

Grinding wastewater from semiconductor packaging plants mainly contains:

✅ Suspended solids (e.g., silicon powder, glass substrate fragments)

✅ Heavy metals (e.g., copper, nickel, lead)

✅ Acidic and alkaline chemicals (e.g., KOH, HNO₃)

✅ Grinding fluids and organics (e.g., ethylene glycol, surfactants)

✅ Residual packaging materials (e.g., photoresists, epoxy resins)

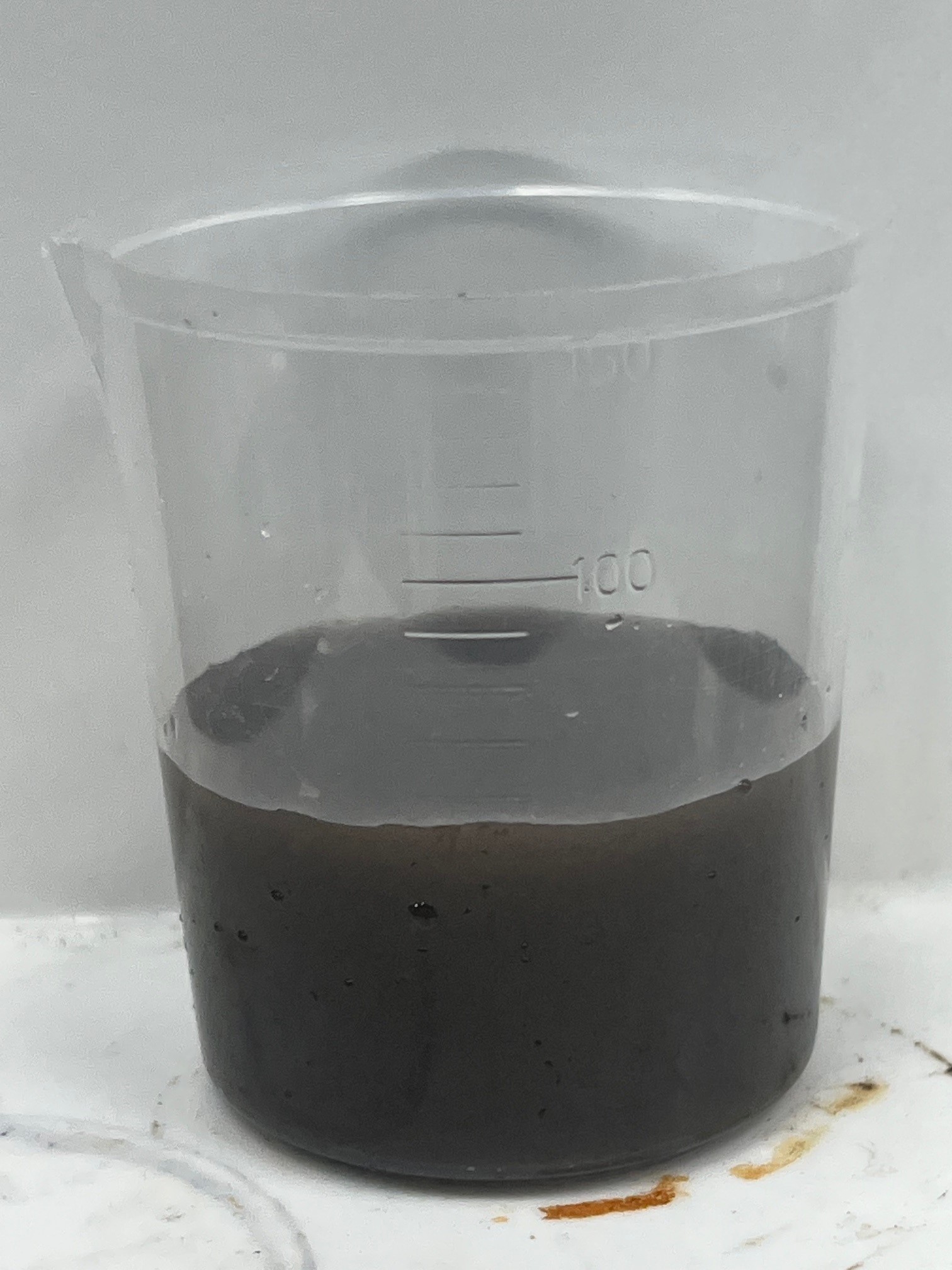

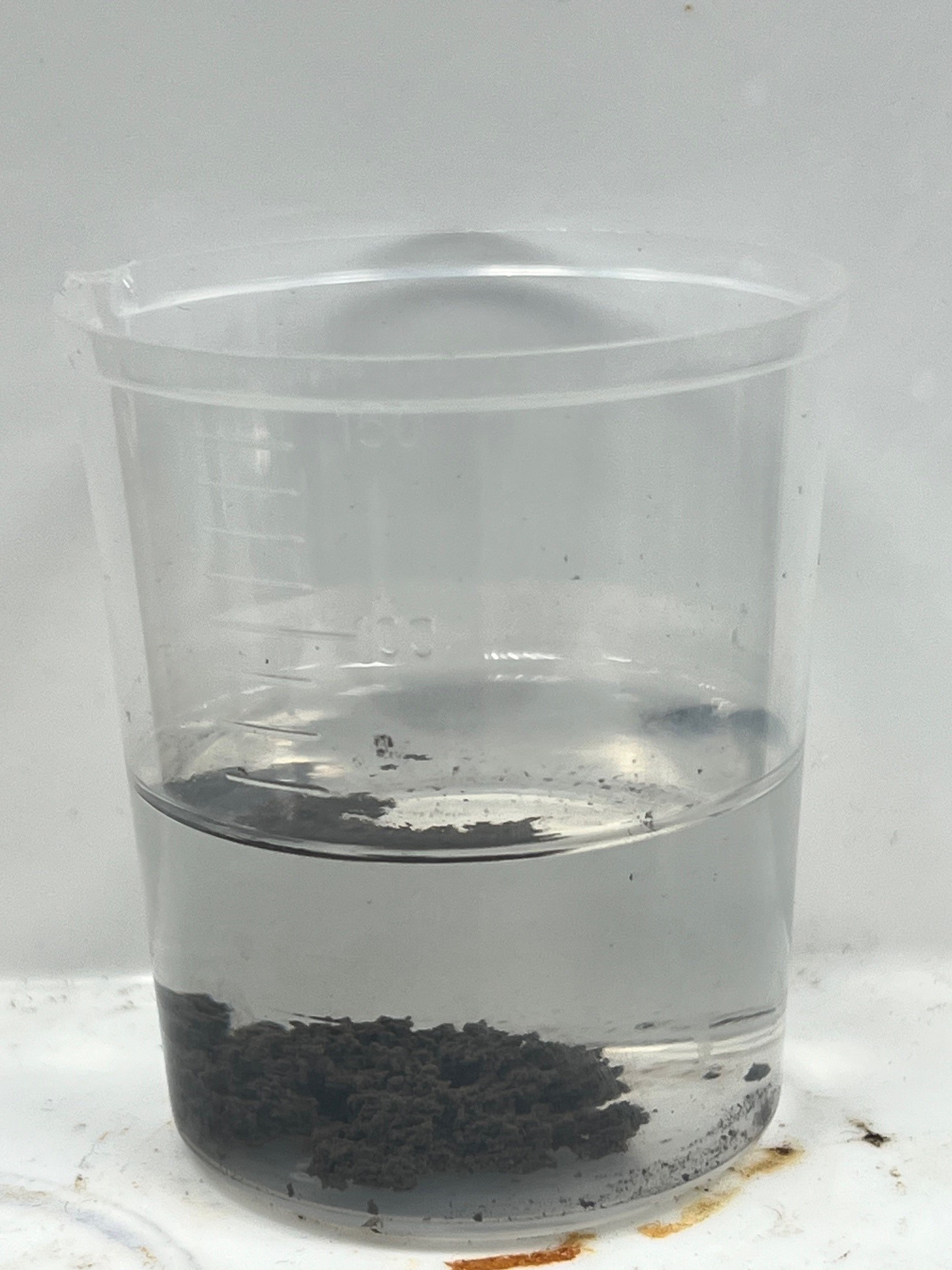

1. Raw Water 2. After addition of A2022

Through the application in this case, the one-dose powder flocculant effectively addressed the challenges of grinding wastewater treatment and improved overall water treatment efficiency.

Our one-dose powder flocculant has been successfully applied across a wide range of industries, helping clients improve water treatment efficiency, reduce operational costs, and meet environmental regulations. If you are looking for an effective and eco-friendly solution for grinding wastewater treatment—or if you have any questions about our products—please feel free to contact us anytime!

CONTACT US

Kelly Chemical Corporation

Electronics

TEL:(02)2762-1985 ext 11200

Online Message

Leave your contact information,

and we will get in touch with you soon.

Email Consultation

After receiving your email,

we will process it as soon as possible.send Email