When hydrocarbon solvents/organic solvents are gradually restricted, how to find a low-cost green cleaning solution?

Cleaning and degreasing have long relied on large amounts of organic solvents, posing not only inefficient cleaning but also high risks!!

Water-based cleaning can be an effective, long-lasting, and sustainable cleaning solution.

For decades, manufacturers, maintenance and repair operations, as well as armed forces, have relied on toxic solvents to clean metal parts. However, as scrutiny over trichloroethylene and other solvents for their health and environmental risks increases, and more companies recognize the benefits of safe and sustainable operational practices, solvent users have been seeking more eco-friendly alternatives.

The emergence of aqueous (water-based) technology offers a cost-effective, environmentally friendly choice for effective, long-lasting, and sustainable cleaning and degreasing of metal parts. Green solutions like Bio-Circle cleaning products protect the environment, enhance workplace safety, reduce industrial waste, and improve cost-effectiveness.

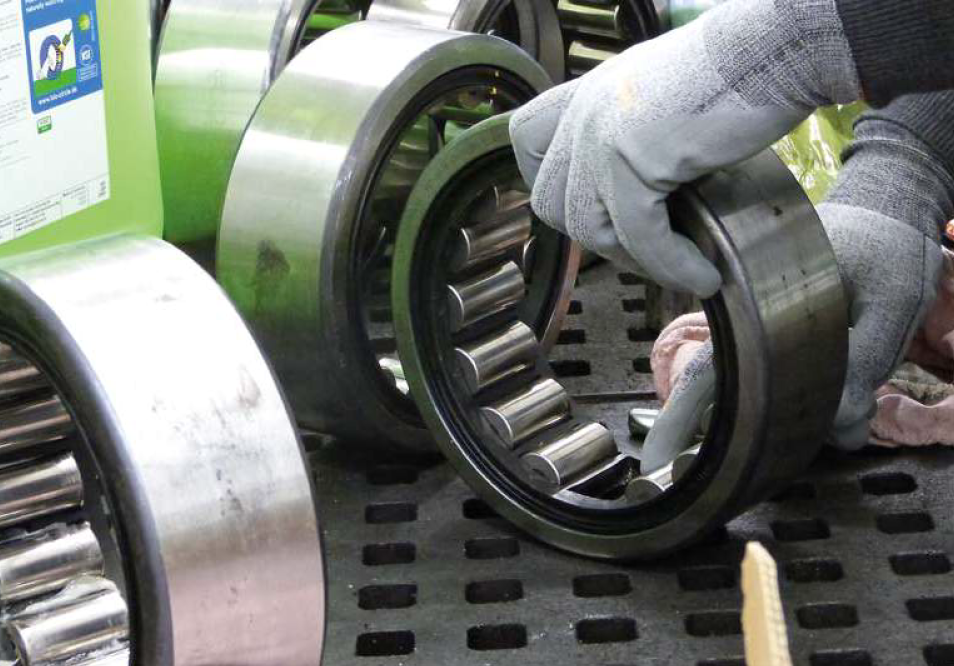

▲Traditional parts cleaning often involves the use of hydrocarbon solvents/organic solvents.

What is aqueous cleaning?

For many years, manufacturers have utilized various hydrocarbon compounds and organic solvents to clean and degrease metal components.These solvents, including trichloroethylene (TCE), methylene chloride, toluene, benzene, mineral spirits, and acetone, are commonly used by manufacturers to clean and degrease metal parts. While chemical solvents effectively remove oils and other liquids from metal parts, many of them pose risks to workers and the environment. Fully chlorinated ethylene and trichloroethylene—two commonly used industrial solvents—are volatile organic compounds (VOCs) associated with many health issues, including an increased risk of cancer. In contrast, water-based cleaning solutions, free of VOCs, offer an environmentally friendly alternative. Unlike many petroleum-based solvents, aqueous cleaning agents are non-flammable. Overall, aqueous cleaners are less toxic than solvents.

Several common methods of aqueous cleaning include:

Immersion cleaning - Parts are immersed in a cleaning solution and agitated and/or heated to provide the energy required to remove contaminants.

Automatic cleaning - High-pressure spraying provides more mechanical action to help remove dirt from parts.

Ultrasonic cleaning - The combination of water, detergent, and high-frequency sound waves produces bubbles that help dissolve and displace particles on parts.

▲Aqueous cleaning is gradually gaining longer-lasting and more sustainable advantages.

Although their cleaning methods differ from solvent-based systems, aqueous cleaners have been proven equally effective. Moreover, due to their safer usage, aqueous cleaners offer many other advantages, contributing to cost reduction. For instance, Inner-Tite Corp., a manufacturer of utility company equipment for anti-tamper security products, transitioned from steam degreasing to an aqueous cleaning system. The Massachusetts-based company was able to eliminate the use of trichloroethylene (TCE) directly. The facility became safer (employees no longer exposed to suspected carcinogen TCE), saving nearly $2,500 annually in trichloroethylene procurement costs.

By reducing the annual usage of 2,675 pounds of trichloroethylene, the company no longer needs to report its trichloroethylene use to state environmental authorities, saving an additional $1,100 annually in regulatory reporting fees. Removing trichloroethylene specifically from its facility took time for emergency response and compliance with OSHA and environmental regulations, while also reducing air emissions to below the threshold for minor source generators.

▲Aqueous cleaning agents (right) have 5-10 times the cleaning lifespan compared to organic solvents (left).

Aqueous cleaning simultaneously biodegrades oil contaminants

Bioremediation is another turning point in aqueous cleaning. The bioremediation process has existed in nature for millions of years and has been widely used to provide a safe, alternative solvent-based cleaning system. In the bioremediation process, active microorganisms in aqueous cleaning solutions decompose oils, fats, and other organic pollutants. Typically, this process occurs in a part cleaning tank, and the bioremediation fluid needs to be heated for optimal performance. Similar to how humans live by eating, breathing, and producing waste, microorganisms consume and digest pollutants and convert them into harmless by-products: primarily water and carbon dioxide. The following is the reaction pathway of microorganisms to fats and other organic substances:

▲Biological cleaning agents simultaneously clean and decompose grease.

Microorganisms break chemical bonds in complex hydrocarbon chains, gaining some energy from this process, and the molecules present in simpler chemical forms, such as water and carbon dioxide. This is a completely natural process. By converting oils, fats, and other pollutants into harmless by-products, bioremediation can help companies reduce their chemical waste footprint—not just in factory workshops. Bioremediation has been used to help clean up large-scale environmental accidents, including the 2010 BP oil spill, which released nearly 500 million gallons of oil into the Gulf of Mexico.

(Extended Reading: Replaces solvent cleaning ~ The best choice for parts and maintenance cleaning, a cleaning solution that does not harm human health! )

From the above, it can be seen that the decomposition ability of microorganisms is quite rapid and evident, leading to the emergence of bio-enhanced cleaning methods, which have clearly become a new industrial cleaning solution. Industrial bio-cleaning is convenient, economical, and solves the problem of difficult waste disposal, greatly reducing industrial waste. At the same time, it also protects employees and the environment from the harm of high-volatility solvents such as kerosene and solvents.

Currently, there are three types of bio-cleaning products on the market. The first type directly incorporates microorganisms as one of the cleaning agents, which users can directly pour into the cleaning tank for use, making it convenient with no complicated operating instructions. The second type compresses microorganisms into tablets, which are added to the cleaning solution in the tank, and microbial sources are replenished regularly. The third type embeds microorganisms in a filter, allowing cleaning to simultaneously introduce microorganisms into the tank liquid, combined with aeration to create an aerobic environment for grease decomposition.

Due to their ability to decompose organic substances such as grease, microbial-type cleaning solutions have a longer lifespan and can be reused repeatedly like kerosene and solvents. Moreover, even high grease and oil pollution can be biodegraded to achieve good cleaning results. Ensuring its effectiveness and cost-effectiveness, while being harmless and environmentally friendly.

▲ Bio-cleaning agents are often paired with a designed system for circulation cleaning, extending their lifespan.

(Excerpted from: Aqueous Cleaning Solutions Drive Safety and Profitability, Production Machining, September 2016)

CONTACT US

Kelly Chemical Corporation

Electronics

TEL:(02)2762-1985 ext 11200

Online Message

Leave your contact information,

and we will get in touch with you soon.

Email Consultation

After receiving your email,

we will process it as soon as possible.send Email