Welding and Cutting~ Welding slag solution E-Weld 3 easily removes welding slag, water-based and easy to clean (replaces manual grinding and oil-based anti-slag)!!

Removing slag, still spending time manually polishing!? Traditional oil-based anti-slag causing trouble in subsequent processes!?

New water-based anti-slag solution!! BIO-CIRCLE E-Weld 3 Anti-Slag ~ Spray ~ Removal Goodbye slag!!

Solution for Welding Spatter Release

E-WELD 3 is a unique high-performance welding spatter release solution that protects workpieces from the adhesion of high-energy spatter and eliminates costly spatter removal operations. Spraying back and forth before welding easily removes slag, making subsequent slag removal processes less burdensome.

.png)

Features and Benefits:

- Protects workpieces and welding equipment from welding spatter

- Water-based formula

- Suitable for MIG and MAG welding operations as well as laser cutting applications

- Formulation prevents adhesion of high-temperature welding spatter. Other applications include stainless steel welding, multi-pass welding, thin plate welding

- Preheat workpieces before welding

- Multi-purpose product! Can also be used as a degreaser for pre-welding preparation.

- Contains temporary corrosion protection corrosion inhibitors

- Multi-purpose product, works equally well in wet or dry conditions

- Excellent paint adhesion—no need for special cleaning operations after welding

- Compatible with aluminum, steel, and stainless steel

- Non-flammable, solvent-free, mineral oil-free, and silicon-free

- Biodegradable

Application:

1.Spray the product on the area to prevent spatter, wearing welding protective equipment, spray the product from a distance of more than 30 cm.

2.Do not spray the product more than 2 times per area.

3.After welding, wipe off the remaining agent and slag with a cloth.

.png)

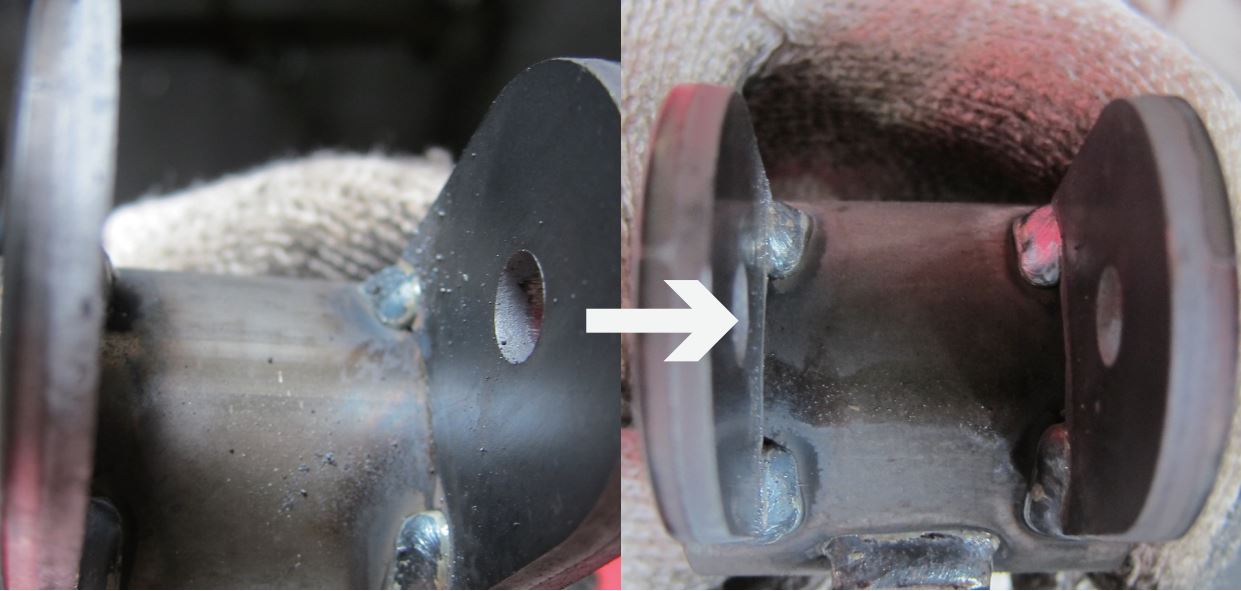

Real Case:

Metal processing factory in Taichung

No anti-slag agent was used originally, and after welding, the spattered slag had to be manually polished, which was time-consuming and labor-intensive.

Spraying E-Weld 3 water-based anti-slag agent back and forth before welding, the spattered slag can be easily removed and does not adhere heavily to the workpiece, making it easy to clean.

▲Water-based slag resistance is particularly suitable for difficult manual polishing and complex structural welds.

Introduction video of German water-based slag resistance agent:

CONTACT US

Kelly Chemical Corporation

Electronics

TEL:(02)2762-1985 ext 11200

Online Message

Leave your contact information,

and we will get in touch with you soon.

Email Consultation

After receiving your email,

we will process it as soon as possible.send Email